Table of Contents

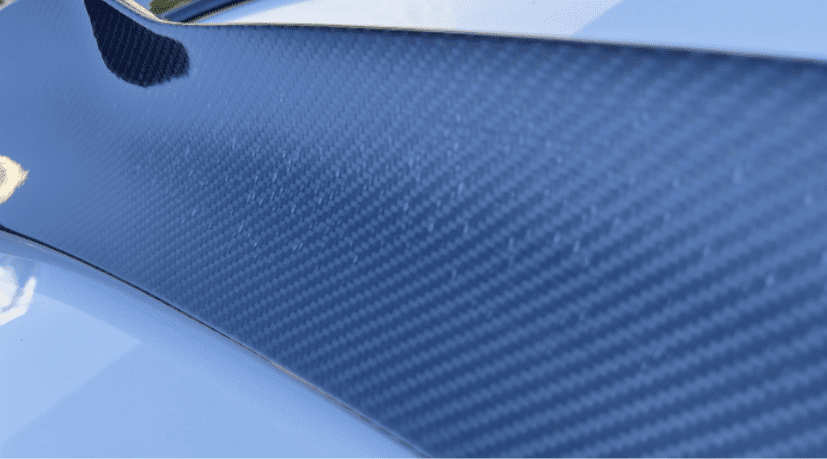

1. Introduction: Why Surface Quality Defines Carbon Fiber Value

In the automotive and aerospace industries, surface perfection equals brand reputation.

A flawless carbon fiber hood, spoiler, or mirror cover is more than aesthetics—it’s proof of engineering precision.

However, even minor defects such as white spots and bubbles can instantly degrade the perceived value of a part. They make products look unreliable, and worse, they may indicate hidden weaknesses that cause delamination or premature failure.

At JCSPORTLINE, we believe quality is not inspected at the end—it’s engineered from the first layer.

With 20+ years of experience as an OEM/ODM carbon fiber manufacturer, we’ve developed a proven process to eliminate surface defects and deliver cosmetic-grade carbon fiber finishes trusted by global brands.

2. Understanding Carbon Fiber Defects: White Spots and Bubbles

2.1 The Real Cost of Defects

White spots or bubbles may seem like small imperfections, but for OEM partners, they mean:

- Higher rework and warranty costs

- Increased return rates and customer dissatisfaction

- Damaged brand credibility in competitive markets

Each defect is a risk multiplier across your entire production line.

2.2 Common Causes of White Spots and Bubbles

- Material Inconsistency – Variations in resin chemistry or fiber porosity trap air during curing.

- Improper Clear Coat Mixing – Wrong ratios or poor atomization create microbubbles.

- Poor Vacuum and Venting Control – Without proper vent channels, trapped air expands during heat curing.

- Limited Inspection Capability – Visual checks alone cannot detect sub-surface air pockets.

OEM Insight: Each 1% increase in surface defect rate can raise finishing costs by up to 5% per batch.

3. JCSPORTLINE’s Proven OEM Process to Prevent Defects

Our OEM carbon fiber manufacturing process combines precision engineering, controlled environments, and smart inspection technology to ensure defect-free production consistency.

3.1 Optimized Layup Design

Each carbon fiber layer is placed in a staggered orientation to ensure even resin distribution.

We integrate venting channels between layers to let trapped air escape naturally during vacuum pressing.

This ensures consistent pressure across the surface—preventing both resin pooling and air entrapment.

3.2 Controlled Resting Stage

After layup, each part rests for 4–6 hours in a humidity- and temperature-controlled environment (22–24°C, <60% RH).

This critical waiting period allows micro-bubbles to rise and dissipate before curing.

Skipping this step often leads to pinholes, white patches, or layer separation visible only after coating.

3.3 Precision Spraying & Long-Duration Baking

All parts are coated using imported clear coats in filtered spray booths.

We employ low-temperature, long-duration baking cycles to stabilize resin expansion and achieve deep gloss and transparency.

This eliminates trapped air bubbles and ensures a cosmetic-grade surface finish that meets global OEM standards.

3.4 Smart Quality Control & Traceability

JCSPORTLINE implements a multi-stage quality control system supported by digital traceability:

- Polarized-light microscopy to detect sub-surface defects invisible to the naked eye.

- Gloss & abrasion resistance tests to validate long-term surface durability.

- ERP-integrated batch tracking, ensuring every component can be traced from raw material to final inspection.

Quality Data: Our defect rate is consistently under 1% across all OEM production runs.

4. Wet Carbon vs. Dry Carbon: Which is Better for OEM Programs?

| Aspect | Wet Carbon | Dry Carbon (Prepreg) |

|---|---|---|

| Resin Application | Manual | Pre-impregnated under controlled ratio |

| Weight | Heavier | 10–20% lighter |

| Surface Quality | Operator-dependent | Uniform and flawless |

| Stability | Moderate | Excellent (OEM & motorsport-grade) |

| Ideal Use | Entry-level parts | Premium performance parts |

For OEM customers demanding stable surface appearance, Dry Carbon Prepreg is the superior choice.

It provides consistent fiber alignment, better dimensional control, and improved resistance to white spot formation.

5. Environmental Control: The Hidden Key to Consistent Quality

Even the smallest environmental fluctuation can cause surface instability.

That’s why JCSPORTLINE maintains strict environmental protocols:

- Constant temperature and humidity across workshops.

- Resin and fiber stored in sealed, moisture-proof containers.

- Spraying and curing performed in positive-pressure clean rooms.

This proactive environmental management minimizes resin crystallization, prevents moisture-induced bubbles, and ensures ISO/IATF-level surface consistency.

6. Real OEM Case Study: From 10% Returns to <1% Defect Rate

A European automotive client once faced 10% returns due to white spots and bubbles on carbon fiber hoods.

After adopting JCSPORTLINE’s optimized layup, curing, and inspection process:

- Complaint rate dropped to below 1%

- Surface gloss improved by 30%

- Average production time reduced by 20%

- Repeat orders increased across three consecutive quarters

This partnership proved that defect prevention, not correction, is the fastest path to profitability.

7. Why OEM Brands Choose JCSPORTLINE

| Advantage | Description |

|---|---|

| Defect-Free Manufacturing | Our layup, spraying, and curing processes maintain <1% surface defect rate. |

| OEM/ODM Flexibility | Support for private labeling and low-MOQ orders. |

| Shorter Lead Times | Parallel curing and automated QC reduce production delays. |

| Global Experience | Trusted by OEM clients across Europe, North America, and Asia. |

| Engineering Collaboration | From 3D scanning to mold optimization, our team integrates seamlessly with client R&D. |

Our philosophy: Quality is not inspected—it’s designed, engineered, and controlled.

8. Common Questions from OEM Partners

Q1. Why do white spots appear on carbon fiber parts?

They are usually caused by trapped air, incorrect resin ratios, or uneven curing conditions. JCSPORTLINE’s venting and baking systems eliminate these issues from the source.

Q2. Can white spots and bubbles be repaired?

Small defects may be sanded and recoated, but repair adds cost and time. Prevention through controlled layup and curing is far more effective.

Q3. Is dry carbon better for premium parts?

Yes. Dry carbon offers better surface stability, uniformity, and long-term durability—ideal for OEM-grade products.

Q4. How does JCSPORTLINE ensure consistent quality?

We apply digital batch traceability, in-line microscopic inspection, and ISO-compliant documentation for every OEM order.

9. Take Action — Partner with JCSPORTLINE

If you’re facing white spots, bubbles, or inconsistent finishes in your carbon fiber production, JCSPORTLINE can help.

Our OEM manufacturing systems deliver measurable results: lower defect rates, shorter lead times, and a flawless finish your clients will trust.

📩 Contact our engineering team today to request a process review or OEM sample.

Let’s build your next carbon fiber project—engineered for perfection.