Table of Contents

Why the Right Manufacturer Decides Your Product’s Profit & Reputation

Choosing the wrong carbon fiber manufacturer can bury your project under hidden costs and reputational damage. Imagine a supplier overpromising on delivery timelines—only to force you into last-minute re-tooling costing $50k+ or delayed product launches. Warranty claims from defective parts could erode margins further, while a single flawed lay-up might cascade through your Bill of Materials (BOM), inflating pricing and damaging customer trust.

JCSPORTLINE flips this script by embedding rigorous engineering controls from the start. Our proprietary “MarginGuard” system identifies cost-saving opportunities early in design, while ISO-certified production ensures zero-defect runs. Partnering with us protects your profit margins and brand equity—because a carbon fiber part failure isn’t just a mechanical issue; it’s a brand credibility crisis waiting to happen.

Separate Real Capabilities from Marketing Gloss

Tooling & Mold Development—Can They Own the Critical Path?

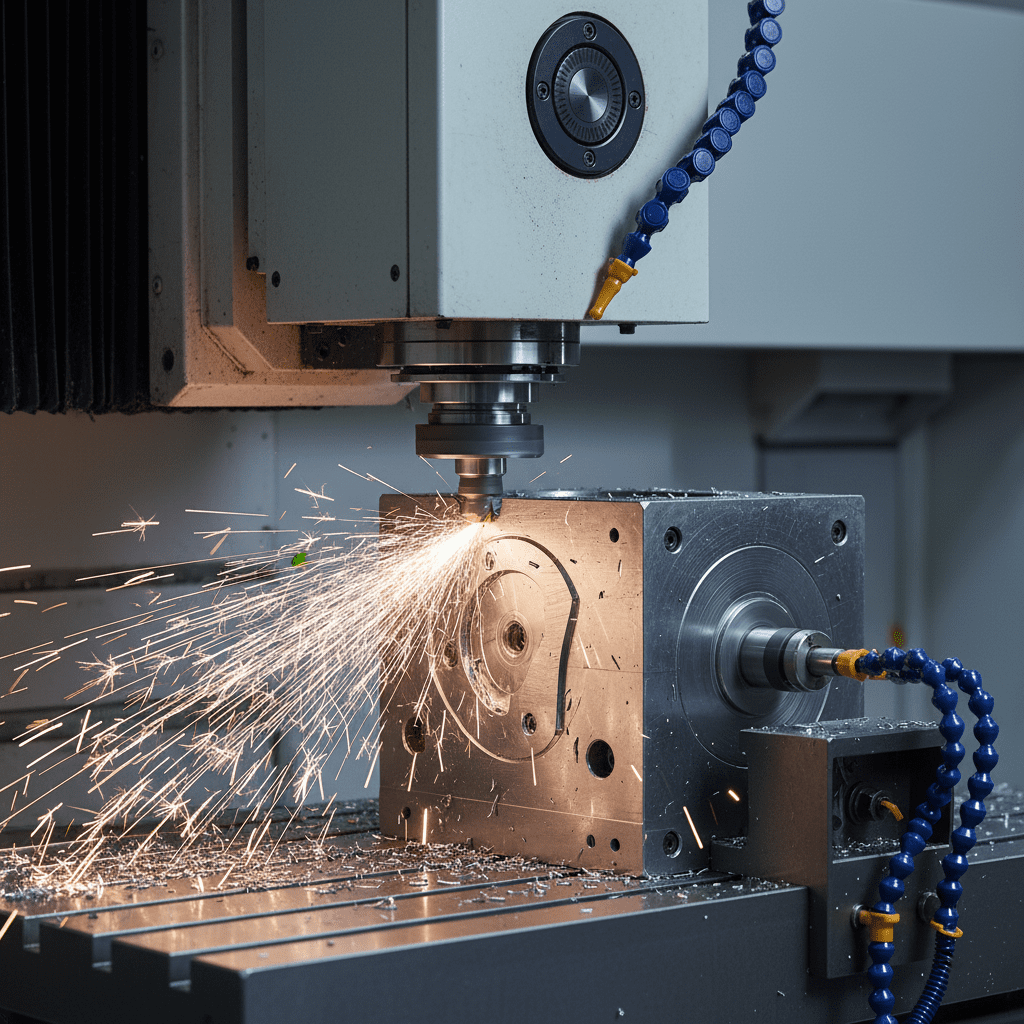

True capability starts with in-house tooling mastery. Ask suppliers: Do they use CNC master patterns or outsource them? Can they modify molds in rapid loops without costly iterations?

JCSPORTLINE’s Edge:

- 5-axis CNC milling cells reduce tooling lead-times by 30% vs. industry averages

- IP-secure workflows keep your designs locked in our Pacific-side facilities

- Rapid mold iteration using aluminum master patterns cuts prototyping cycles by 40%

| Tooling Type | Industry Lead-Time | JCSPORTLINE Lead-Time |

|---|---|---|

| Metal molds | 8-12 weeks | 6-8 weeks |

| Composite | 6-10 weeks | 4-6 weeks |

Material Control & Lay-up Strategy — Auditing the Carbon Stack

Every layer of a composite part represents a critical quality control point. At JCSPORTLINE, material control and lay-up consistency are ensured through standardized inspection procedures and process-driven verification, rather than assumptions or unchecked automation.

Our material and lay-up control framework includes:

- Fiber Source Verification:

Qualified prepreg carbon fiber materials sourced from approved suppliers, such as Torayca, verified through incoming quality inspection (IQC).- Resin System Validation:

Resin systems are selected according to project requirements and validated through internal testing and customer-specified standards, ensuring stability and long-term performance.- Controlled Storage & Handling:

Prepreg materials are stored and managed under controlled temperature conditions, with storage records maintained to ensure material consistency prior to lay-up.- Lay-up SOP & Process Control:

Ply orientation, stacking sequence, and trimming locations follow defined SOPs established by the R&D team, with in-process quality control (IPQC) monitoring critical steps during production.- First Article & Batch Validation:

First samples and mass-production parts are compared and validated through dimensional inspection, performance testing, and customer-approved standards before full-scale production.

JCSPORTLINE Quality-Control Innovation:

Instead of relying on marketing-driven tracking concepts, JCSPORTLINE ensures delivery accuracy and material consistency through an AI-assisted quality management system integrated with ISO-certified SOPs.

From incoming raw material inspection (IQC) to in-process control (IPQC) and final quality control (FQC), our system continuously monitors key process parameters, compares pilot samples with mass-production parts, and flags deviations before they impact delivery schedules or part performance.

This data-driven approach allows us to maintain stable lead times, consistent lay-up quality, and reliable batch-to-batch performance—supporting precise project execution without compromising quality or delivery commitments.

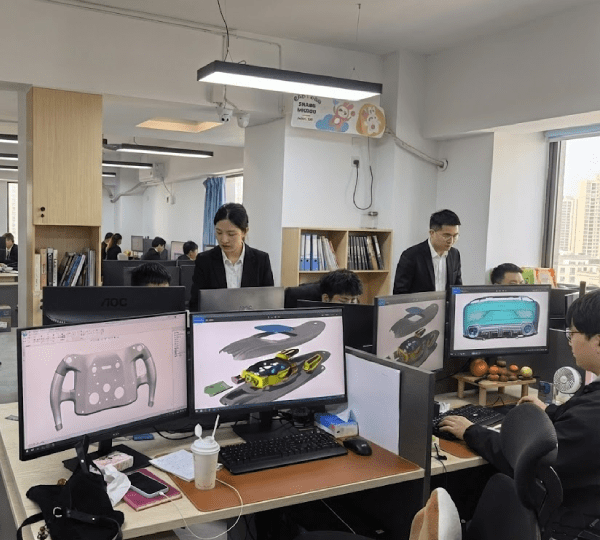

Engineering Support vs. Build-to-Print—Who Adds Value?

Many factories operate as “CAD-to-CAVE” shops, blindly reproducing designs that may contain hidden inefficiencies. True partners like JCSPORTLINE offer:

Case Study:

A racing gear manufacturer sought a 12% weight reduction for a diffuser rib. While competitors quoted 14% cost increases, we:

- Redesigned using topology optimization to save 12% weight

- DFMA analysis identified 8% material cost savings

- NVH simulation ensured noise levels met F1 regulations

Scalability, Consistency & Risk Control—From 10 Units to 10k

Production Phases:

- Pilot Cell: 5-axis machining for prototypes

- Autoclave Batches: ±0.1% tolerance control via real-time pressure/temperature mapping

- Compression Mold Lines: Mass production at Cpk >1.67, void content <1%

Risk Mitigation:

- Dual-factory redundancy in China/EU

- Global shipping supported through multiple logistics and warehousing locations.

- AI-driven yield analytics predicts quality issues 72 hours before they occur

7 Red Flags That Kill Projects (Checklist)

- No Material Certs: Ask for third-party test reports

- Single Autoclave: Reduces production flexibility

- No NDT Map: Non-destructive testing should cover 100% of critical parts

- Ghost Shift Photos: Reject suppliers using stock images for “production lines”

- MOQ > Annual Forecast: Traps you in inventory risks

- Expiring NDAs: Legal loopholes for IP theft

- Alibaba-Only Address: No physical factory verification

What a Long-Term B2B Partner Looks Like

A strategic partner should evolve with your business:

- 3-Year Roadmap:

Year 1: Joint cost-down targets

Year 2: Co-developed patents

Year 3: ESG score integration - Dedicated Program Office: Your single point of contact for engineering, compliance, and logistics

FAQ – Quick Answers for Procurement & Engineering Teams

Q1: What does a custom carbon fiber manufacturer actually do?

We translate your material specs (fibers, resins, geometries) into repeatable production processes, including:

- Tooling design/maintenance

- Lay-up/autoclave curing

- Full PPAP documentation

Q2: How do I evaluate a factory’s engineering capability?

Request:

- Live DFMA walk-through

- FEA report samples

- References from clients with similar annual volumes

Q3: Can custom parts scale to mass production?

Yes—if the vendor has:

- Multi-process cells (autoclave/RTM/compression)

- Cpk consistency tracked from pilot to SOP

Q4: What certifications matter?

- ISO 9001 for quality

- IATF 16949 for automotive

- AS9100 for aerospace

- ISO 14001 for ESG compliance