Table of Contents

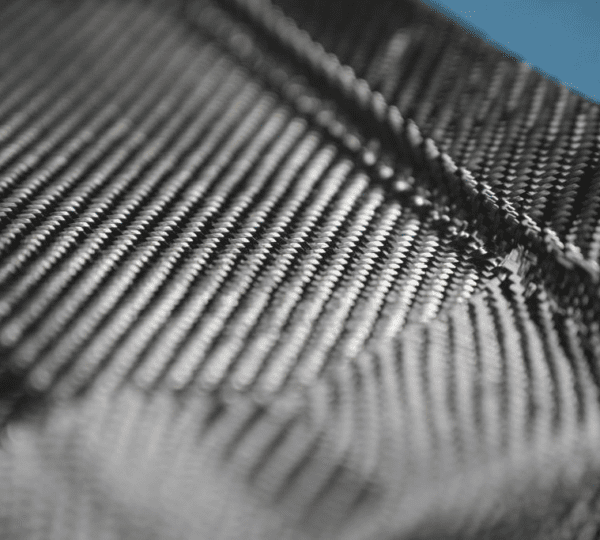

Carbon fiber car parts are popular among car enthusiasts and businesses because they are lightweight, rigid, and extremely strong. However, being light doesn’t mean they’re unbreakable. During carbon fiber car parts shipping or installation, parts can get damaged or slightly warped if not handled properly. So how can you make sure your carbon fiber parts arrive in perfect shape and fit perfectly during installation?

In this blog, we’ll show you how professional packaging ensures stability, safe shipping, and a smooth installation experience—highlighting the benefits of choosing an experienced manufacturer like JCSPORTLINE.

The Challenges of Shipping Carbon Fiber Parts

Even though carbon fiber is a high-tech material known for performance and durability, it is more fragile than metal. During shipping, bumps, pressure, or forces from stacking can cause parts to warp or get scratched. Temperature changes and humidity can also affect the part’s shape and energy absorption.

For car enthusiasts, a perfect fit and flawless look are very important. For business clients, like car shops or dealerships, shipping safety and efficiency matter even more. Choosing the right packaging is the first step to keeping car parts safe and maintaining their quality.

Different Customers, Different Needs

JCSPORTLINE serves both C-end (consumer) and B-end (business) customers, and their needs are different:

- C-end (Consumer) Customers: Car enthusiasts, sports car or performance car owners who care about appearance and installation experience. They expect parts—whether a spoiler or a hood—to arrive perfectly intact, with no compromise in quality.

- B-end (Business) Customers: Car modification shops, dealerships, or repair shops that require large orders and efficient, safe shipping. They need custom solutions that offer both speed and reliability without losing packaging quality.

JCSPORTLINE tailors carbon fiber packaging solutions to meet different customer needs, ensuring all parts arrive in perfect condition without wasting time.

JCSPORTLINE’s Professional Packaging Solutions

To protect carbon fiber parts during shipping, JCSPORTLINE uses multiple packaging methods:

- Carbon Fiber Protective Packaging – For lightweight and stable parts, prevents scratches and minor bumps.

- Foam Packaging – Absorbs shocks and protects delicate edges.

- Wooden Crates – For large or easily warped parts like a carbon fiber hood, providing strong protection.

- Custom Packaging Strategy – Every part is packaged based on size, materials, and fragility for maximum safety and consistent quality.

With these customized solutions, JCSPORTLINE ensures parts maintain their shape, even during long-distance shipping. Each step follows strict procedures, almost like checking a packaging code line by line, leaving no room for error.

Shipping Stability and Installation Experience

Professional packaging isn’t just about safe shipping—it also affects installation. JCSPORTLINE’s multi-layer protection keeps parts from moving or shifting during transport. When the customer receives the part, it fits perfectly without adjustment, ensuring a smooth installation.

This strategy reduces risk for both consumers and business clients and guarantees a professional finish. It helps shops save a lot of effort and prevents costly stops in the workflow. With this attention to detail, the overall quality of the installation experience reaches a higher level.

Real Customer Examples

- A customer in the U.S. ordered a BMW G82 M4 carbon fiber rear wing. After long-distance shipping, the part arrived in perfect condition and fit perfectly during installation. The customer said:

“The packaging is very professional. My carbon fiber part arrived without a single scratch or warp.”

- A car modification shop ordered a large batch of carbon fiber front lip kits. Thanks to custom packaging, all parts arrived safely and installation was completed quickly, improving workflow and efficiency to a new level.

These examples show the real-world benefits of professional packaging and strict quality standards in carbon fiber shipping.

Choosing a supplier with professional packaging and shipping experience is essential for carbon fiber part stability. With over 20 years of experience, JCSPORTLINE provides custom packaging solutions that ensure every part arrives intact and ready for a perfect installation.

Whether you are a car enthusiast or a business client, professional packaging ensures safety, efficiency, and a flawless installation experience.

Contact us today via email or schedule a visit to our facility to see how your carbon fiber parts can be designed, shipped, and installed perfectly. Let’s continue building the future of performance upgrades together!