Table of Contents

🏄♂️ Introduction

Saltwater is the ultimate test for every hydrofoil surfboard. While carbon fiber itself doesn’t rust, many riders are surprised to find tiny spots of corrosion appearing around their screws, inserts, and motor housings after only a few months of use. The issue isn’t with the carbon—it’s with the metal components that connect and seal your board.

When saltwater seeps into these connection points, it triggers galvanic corrosion — a slow electrochemical reaction between carbon fiber (a conductive material) and metal hardware. Over time, this leads to rust, weakened joints, and even water leakage into the battery compartment.

In this guide, we’ll explain why corrosion happens, how to identify early warning signs, and the engineering solutions JCSPORTLINE uses — including 316L stainless steel inserts, marine-grade coatings, and advanced sealing designs — to make your hydrofoil surfboard truly resistant to saltwater and built to last.

1. Understanding Saltwater Corrosion

Saltwater is one of the most corrosive environments on earth. It contains dissolved salts and minerals that make it highly conductive, allowing electricity to flow easily between different materials. When metal components are exposed to saltwater, this conductivity accelerates oxidation — the chemical process that produces rust and weakens the metal over time.

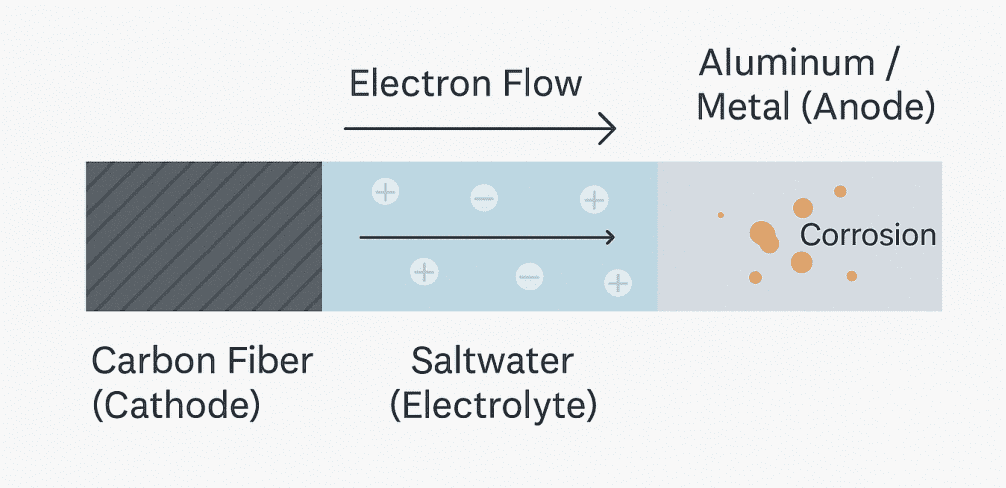

While carbon fiber itself is corrosion-resistant and chemically inert, it is also electrically conductive. That means when carbon fiber comes into contact with dissimilar metals such as aluminum or low-grade stainless steel, it can create what’s known as galvanic corrosion. In this process, carbon fiber acts as a cathode and the metal becomes the anode, slowly sacrificing itself through electrochemical reactions.

In a hydrofoil surfboard, this issue often appears in the areas where carbon and metal meet — such as motor housings, screws, inserts, battery compartments, and electrical connectors. Over time, tiny voltage differences combined with saltwater exposure can lead to visible corrosion, seized screws, and even leakage around hardware points.

Understanding this mechanism is the first step toward stopping it. Once you know that the problem comes not from the carbon fiber itself, but from the metal-to-carbon interfaces, you can start applying engineering solutions — including marine-grade metals, protective coatings, and insulation design — to make your surfboard truly saltwater-proof.

2. The Real Cause: Galvanic Corrosion with Carbon Fiber

At first glance, it’s easy to assume that the carbon fiber in your hydrofoil surfboard might be the problem — but the truth is more complex. Carbon fiber itself doesn’t rust, yet it behaves like a powerful electrical conductor. When paired with metal components in the presence of saltwater, this conductivity sets up a tiny galvanic cell, which becomes the root cause of corrosion.

Here’s what happens in simple terms: When carbon fiber (the cathode) comes into contact with metals such as aluminum or low-grade stainless steel (the anode) and saltwater acts as an electrolyte, a microscopic electrical current begins to flow between the two materials. Over time, this electron exchange causes the metal to oxidize and break down, leaving behind the familiar signs of corrosion — pitting, discoloration, or even complete material loss.

In real-world use, this often shows up around screws, inserts, or motor mounts, where carbon fiber and metal are tightly bonded together. Many mass-produced boards that use cheap aluminum inserts start to show white oxidation spots or brown rust stains after just a few months of saltwater exposure. Once corrosion begins, it can spread beneath the surface, weakening threads and eventually causing leaks or hardware failure.

Understanding galvanic corrosion explains why even premium-looking surfboards can fail prematurely — and why choosing the right metal alloys, coatings, and insulation techniques is essential to long-term durability in marine environments.

3. Choosing the Right Hardware: Marine-Grade Metals

Once you understand that corrosion starts where metal meets carbon, the next step is choosing the right hardware. Not all “stainless steel” is created equal. Many entry-level hydrofoil boards still rely on 304-grade stainless or aluminum inserts, which may look shiny at first but quickly corrode when exposed to saltwater and carbon fiber contact.

For true marine performance, you need 316L stainless steel — a low-carbon alloy specifically designed for high-salinity environments. Unlike cheaper grades, 316L contains added molybdenum, which dramatically improves its resistance to chloride-induced corrosion and pitting. This makes it the gold standard for yachts, diving equipment, and now, premium hydrofoil surfboards.

At JCSPORTLINE, every bolt, nut, and insert used in our carbon fiber boards is 316L marine-grade and undergoes anti-corrosion surface treatment before assembly. This means each metal component is pre-treated and sealed before it touches the carbon fiber shell — not coated afterward as a cosmetic fix.

Each batch of hardware passes a 24-hour salt-spray test (ASTM B117) to simulate long-term seawater exposure. The result:

✅ A service life of over three years in active marine conditions.

✅ No galvanic reaction between the carbon fiber structure and metal fasteners.

✅ Zero rust marks or leakage around insert zones.

This meticulous approach ensures that every JCSPORTLINE surfboard can handle not only performance stress but also real-world environmental challenges — from daily saltwater sessions to long-term storage in humid coastal climates.

4. Smart Anti-Corrosion Design Strategies

Corrosion protection isn’t just about using better metal — it’s about designing the entire surfboard system to keep saltwater out and prevent elec

trical reactions before they start. At JCSPORTLINE, every detail from the screw insert to the motor compartment follows a layered protection strategy built on sealing, coating, isolation, and active defense.

4.1 Seal Design & Waterproofing

The first line of defense is mechanical sealing. Every insert and fastening point is surrounded by ABS and glass-fiber reinforcement, which absorbs stress and prevents cracks under vibration or impact. Around critical openings such as the battery and motor compartments, precision-machined O-rings and bonded gaskets ensure IPX7-level waterproofing.

Unlike traditional boards that rely on silicone or hand-sealed resin, our sealing structures are integrated into the mold design — meaning fewer joints, fewer leak points, and longer-lasting protection even after hundreds of saltwater cycles.

4.2 Protective Coatings & Plating

Even the best stainless steel benefits from an added layer of protection. JCSPORTLINE hardware receives a dual-stage anti-corrosion finish:

- Electro-polishing or passivation removes surface impurities and enhances chromium oxide film formation.

- Ceramic or PTFE (Teflon) coatings provide an additional non-stick barrier against salt deposits and biofouling.

This combination creates a smooth, low-friction surface that resists both rust and marine growth — keeping your hardware clean, strong, and easy to service.

4.3 Electrical Isolation

Since galvanic corrosion begins when two conductive materials are electrically connected through saltwater, isolation is key. We place insulating washers, sleeves, and composite bushings between metal parts and the carbon fiber shell. These micro-barriers interrupt electron flow, eliminating the galvanic cell effect and preventing corrosion at the source.

This design not only protects the metal hardware but also preserves the structural integrity of the carbon fiber, especially in high-torque areas such as fin bases and motor mounts.

4.4 Sacrificial Anodes (Optional)

For electric hydrofoil systems or heavy saltwater users, we integrate sacrificial anodes made from zinc or magnesium. These small replaceable components intentionally corrode first, “sacrificing” themselves to protect more valuable parts like inserts, propellers, and motor housings. It’s the same principle used in ships and submarines — scaled down for personal watercraft.

By combining passive and active corrosion control, JCSPORTLINE surfboards maintain their appearance and strength long after other boards begin to show rust or leakage.

5. Testing & Quality Control

Every anti-corrosion design is only as good as the testing that proves it. Before any JCSPORTLINE carbon fiber hydrofoil surfboard reaches the water, it goes through a comprehensive multi-stage validation process that simulates years of real-world exposure in just a few days.

5.1 Salt-Spray and Corrosion Simulation

Each batch of hardware and assembled components is tested under ASTM B117 salt-spray conditions, using a 5% NaCl mist at constant temperature and humidity for over 24 hours. This accelerated environment replicates the effect of long-term marine exposure and confirms the surface resistance of our 316L stainless steel inserts, bolts, and fasteners. No oxidation spots, discoloration, or structural degradation are permitted before clearance to production.

5.2 Thermal Cycling & Environmental Endurance

To ensure coatings and sealants remain stable in extreme environments, boards undergo thermal shock tests ranging from –20°C to +60°C, repeated over five full cycles. This verifies that the resin, coatings, and gaskets maintain adhesion and elasticity under both hot sun and cold seawater. Even after repeated expansion and contraction, no cracks or delamination appear on the board’s surface.

5.3 Leak-Proof & Pressure Tests

Every board is placed in a controlled water immersion tank to verify complete waterproofing. The internal compartments — including motor mounts, battery housings, and insert zones — are monitored for any pressure drop or moisture ingress. Only boards that maintain full IPX7 compliance are approved for shipment.

5.4 Vibration & Transport Validation

Because many of our boards are exported globally, packaging integrity and hardware stability are tested under vibration conditions up to 2 g. This ensures that neither transportation nor repeated assembly cycles will loosen the inserts or seals. Combined with our foam-lined custom crates and PE film wrapping, every product arrives ready for immediate use without corrosion risk or surface marks.

5.5 Visual & Dimensional Inspection

Finally, each finished unit undergoes 3D scanning verification, comparing the physical geometry to the CAD model with tolerance ≤ 0.5 mm. This guarantees that sealing grooves, insert placement, and surface finishes remain consistent from prototype to mass production.

Through these strict validation steps — corrosion testing, thermal cycling, waterproof verification, and vibration analysis — every JCSPORTLINE board leaves the factory with proven resistance against salt, heat, and time. It’s not just a surfboard; it’s a marine-engineered system designed to perform flawlessly year after year.

6. How JCSPORTLINE Solves This for You

At JCSPORTLINE, corrosion prevention isn’t treated as an afterthought — it’s engineered into every layer of the surfboard from concept to production. We’ve combined aerospace-grade composite design with marine engineering principles to create a hydrofoil platform that not only performs, but also endures.

Electric Surfboard

Jcsportline Electric Surfboards feature one-piece carbon fiber construction, lightweight PU foam cores with local carbon reinforcements, full-board custom graphics, and marine-grade waterproof components for durable, high-performance water sports.

Here’s how we protect your investment:

✅ Marine-Grade Materials, Tested for the Sea

Every metal part that connects to carbon fiber — from bolts and inserts to motor mounts — is made from 316L stainless steel. Each piece is pre-treated for saltwater resistance and verified through 24-hour salt-spray testing to ensure zero rust even after years of exposure. The result is hardware that lasts 3x longer than conventional surfboard fittings.

✅ Integrated Waterproof Structure

Our surfboards are produced using one-piece compression molding, meaning there are no visible seam lines or potential leak joints. The sealing system — including ABS and glass-fiber reinforcement, O-rings, and bonded gaskets — achieves true IPX7 waterproofing and resists vibration fatigue over time.

✅ Intelligent Design Against Galvanic Corrosion

Through CFD and structural analysis, we’ve optimized not only hydrodynamics but also electrical isolation between carbon and metal. Insulating sleeves and composite bushings are built into the design, stopping galvanic corrosion before it can begin.

✅ Proven Performance, Verified by Testing

All products pass thermal cycling, vibration, and leak-proof tests, ensuring consistent protection under harsh salt, heat, and mechanical loads. Combined with 3D scanning and digital QC, we guarantee every production batch matches the design precision of the prototype.

✅ OEM/ODM Ready for Your Brand

Whether you’re an OEM surfboard manufacturer, a rental operator, or a water-sports brand, our system is fully customizable:

- Logo and graphic branding (up to 1m decals)

- Finish options: gloss, matte, or UV-protected

- Localized reinforcements for racing, rental, or recreation use

- Engineering support from CAD concept to full production

With over a decade of experience in carbon fiber composites, JCSPORTLINE helps you deliver products that are not only fast and lightweight — but also built for real marine endurance.

In short: we don’t just make carbon fiber boards. We engineer complete marine systems designed to resist corrosion, protect performance, and stand the test of salt, time, and speed.

7. Maintenance Tips for Long-Term Protection

Even the most advanced corrosion-resistant surfboard benefits from simple, consistent care. By following a few easy maintenance habits, you can dramatically extend the life of your hydrofoil’s metal parts, seals, and carbon finish — ensuring it looks and performs like new, season after season.

7.1 Rinse Thoroughly After Every Ride

After each session, rinse your surfboard with fresh water to remove any salt, sand, or mineral deposits. Pay special attention to metal inserts, motor housings, and screw heads, where salt crystals can accumulate. Allow the board to dry completely before storage; even a few drops of trapped saltwater can start a corrosion process over time.

7.2 Apply Marine Anti-Corrosion Spray

Use a marine-grade protective spray such as Boeshield T-9, WD-40 Marine, or equivalent. Lightly mist the exposed metal areas — bolts, screws, connectors — after cleaning. These sprays create a micro-film barrier that blocks moisture and prevents oxidation, especially if you ride frequently in high-salinity waters.

7.3 Avoid Mixed Metals

Never combine aluminum brackets or fittings with carbon fiber or stainless hardware. Different metals have different electrochemical potentials; mixing them can restart the galvanic reaction you worked so hard to prevent. When adding accessories, always choose 316L stainless or plastic-isolated parts.

7.4 Inspect Seals and Fasteners Regularly

Every few months, check that all O-rings and gaskets remain flexible and intact. Replace any that appear dry or cracked. Re-torque the screws gently — overtightening can crush seals or break the insulating sleeves that protect against corrosion.

7.5 Proper Storage

Store the board in a dry, ventilated area, away from direct sunlight. If stored in a humid or coastal environment, keep a small dehumidifier pack inside the case. Avoid leaving the board with water trapped in the fin box or motor compartment.

7.6 Scheduled Maintenance for Heavy Users

For rental operators or daily riders, perform a complete corrosion check every 3–6 months:

- Remove and clean all fasteners.

- Reapply anti-corrosion coating.

- Inspect insert zones for any discoloration or residue. This proactive care ensures long-term waterproof integrity and saves costly repairs later.

Pro Tip: A few minutes of fresh-water rinsing and periodic inspection will add years of life to your surfboard — even in the toughest saltwater environments.

8. Conclusion

Saltwater is unforgiving — it exposes every weakness in your board’s design, from unprotected metal inserts to poor sealing and mismatched materials. While carbon fiber itself doesn’t rust, improper material pairing and lack of corrosion control can still lead to oxidation, leakage, and costly damage over time.

That’s why at JCSPORTLINE, we’ve engineered a complete anti-corrosion system — not just isolated fixes. From 316L marine-grade stainless steel hardware and integrated IPX7 sealing, to electrical isolation layers and multi-stage salt-spray testing, every board is designed to perform flawlessly in real marine environments. Our goal is simple: to make hydrofoil surfboards that stay fast, strong, and corrosion-free for years, no matter how often you ride.

Whether you’re an OEM brand, a rental operator, or an enthusiast looking for long-term reliability, our experience in carbon fiber composites and marine engineering ensures your product stands up to both speed and salt.

Ready to make corrosion a thing of the past? Partner with JCSPORTLINE for your next generation of carbon fiber hydrofoil surfboards — designed, tested, and proven to thrive in saltwater.

📩 Contact us today for OEM/ODM inquiries and custom anti-corrosion solutions.