- Home

- Services

- Industries

- Capabilities

- Resources

- Company

JCsportline Marine Series

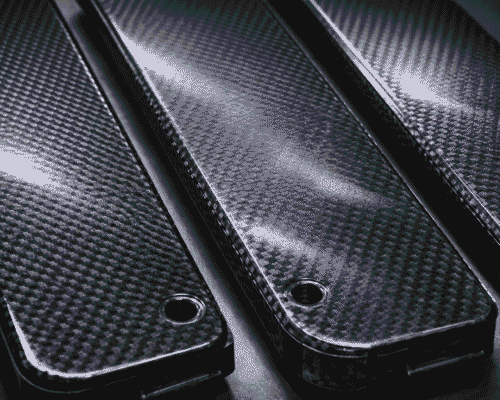

Carbon Fiber Structures Engineered for Marine Environments

JCsportline applies advanced composite engineering to products operating in demanding marine conditions—from electric surfcraft and hydrofoil systems to yacht tenders and professional diving equipment.

The Marine Series is not defined by a single product category, but by a shared engineering standard:

lightweight structures, controlled stiffness, corrosion resistance, and production consistency at scale.

Designed for brands seeking long-term OEM/ODM partnerships, we support your product from structural concept to stable manufacturing—without compromising performance or finish.

What We Build for Marine Applications

A Marine Portfolio Defined by Engineering Standards

Marine environments demand more than lightweight design. Salt exposure, cyclic loads, impact forces, and long service life all require structural discipline and manufacturing consistency.

Our Marine Series brings carbon fiber engineering into water-based products without compromising durability or finish.

Electric Surfcraft & Powered Boards

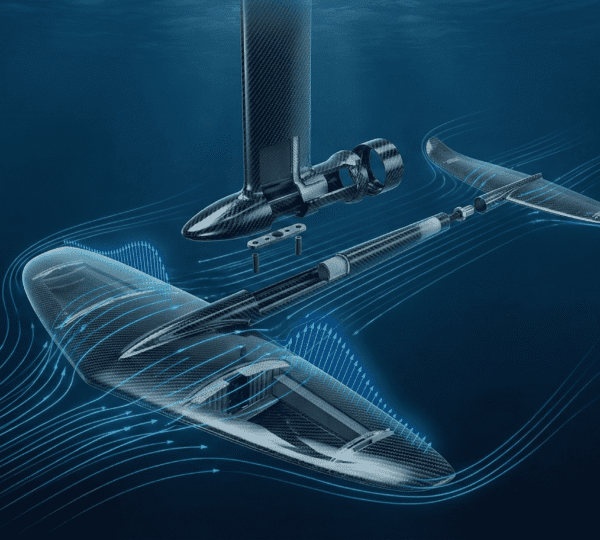

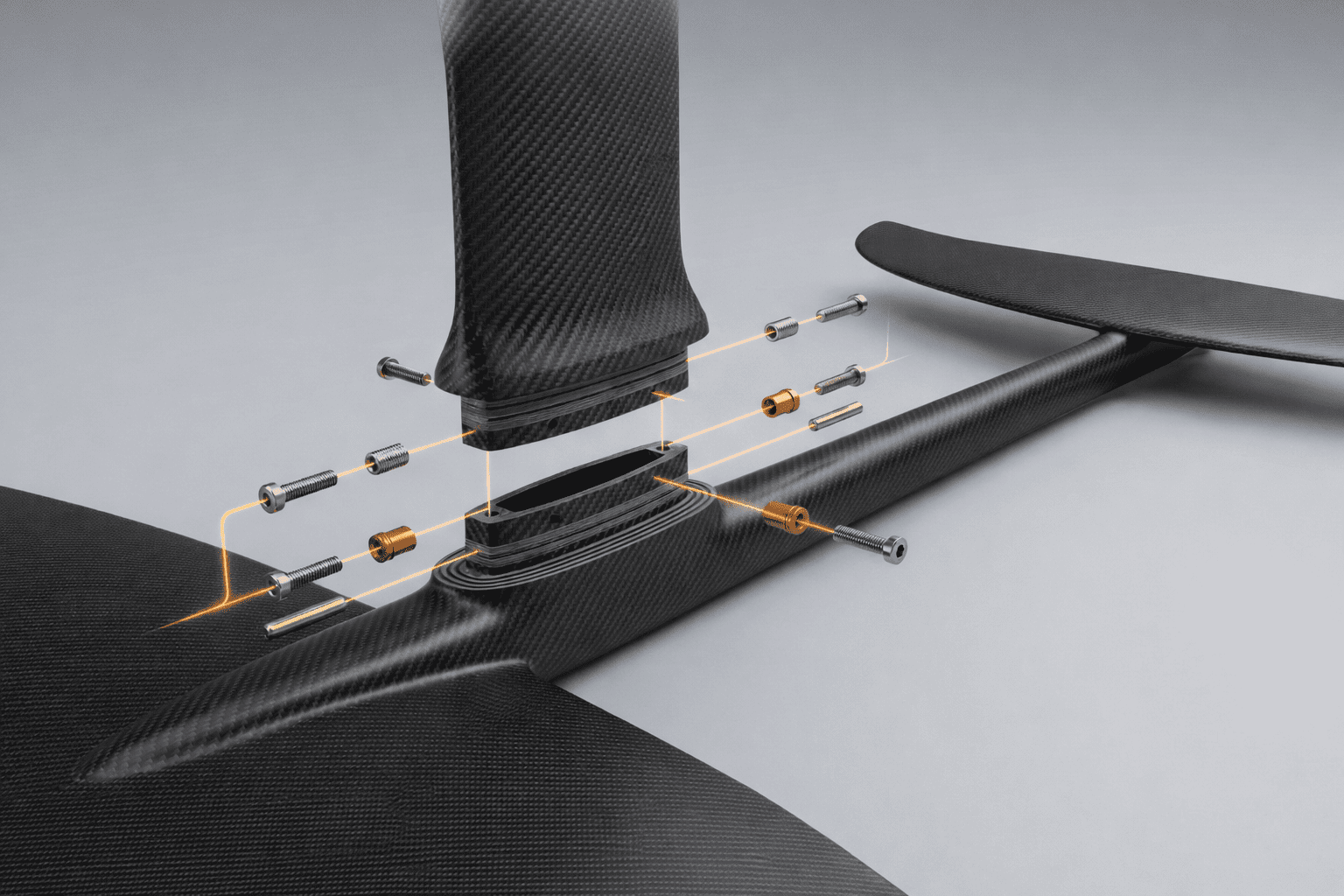

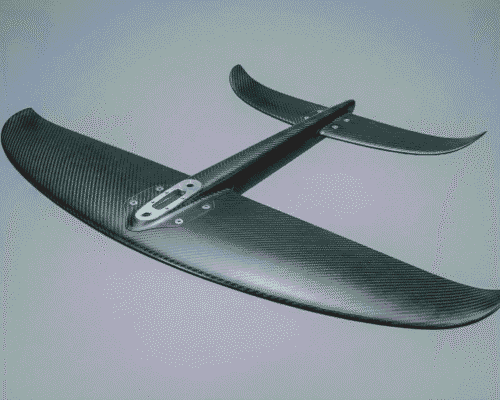

Hydrofoil Systems & Foil Structures

Yacht Tenders & Lightweight Marine Craft

Professional Carbon Fiber Diving Fins

Not All Marine Products Are Built the Same

Water Sports Products vs. Marine-Grade Carbon Fiber Structures by JCSPORTLINE

Why Carbon Fiber in Marine Environments

Lightweight Is Only the Beginning

In marine and water-based applications, carbon fiber delivers value only when structure, process, and quality control work together.

-

Predictable structural behavior through engineered layups and controlled curing

-

High stiffness-to-weight performance for responsive handling and reduced system load

-

Corrosion-resistant composite structures suited for long-term marine exposure

-

Premium surface quality aligned with high-end consumer and yacht branding

Engineering principle

Marine performance is not defined by peak numbers, but by consistency over time.

From Design Intent to Stable Production

Engineering & Manufacturing Capabilities

As a marine composite manufacturer, JCsportline supports OEM and ODM programs with a design-to-manufacture mindset—ensuring that engineering decisions translate cleanly into repeatable production.

Predictable Collaboration, Proven Marine Outcomes

Our approach aligns collaboration, application, and manufacturing—so marine programs stay stable from concept to scale.

Fragmented Collaboration Slows Projects

Engineering Without Application Context Fails

Inconsistent Quality Creates Long-Term Risk

Your Premier Partner in Composite R&D and Manufacturing

WHY JCSPORTLINE

Frequently Asked Questions

Clear answers to common questions about marine carbon fiber engineering, manufacturing, and OEM/ODM collaboration.

Yes. We support OEM and ODM programs from early engineering through stable production for marine and water-based applications.

Yes. Water sports products are included when they require marine-grade structures, durability, and manufacturing consistency.

Our processes are designed for repeatability, documentation, and scalable output—supporting multi-generation product lines.

Share your product concept, performance targets, and expected volumes. Our team will respond with a structured engineering approach.

Build Marine Carbon Fiber Products with Confidence

Bring your concept, drawings, or reference products.

We bring marine-grade engineering discipline, manufacturing stability, and a partnership mindset built for long-term success.