Table of Contents

Looking for high-quality carbon fiber parts that are easy to install and built to last?

JCSPORTLINE offers carbon fiber components with OEM-style clip-on mounting, eliminating the need for glue and reducing installation time and warranty issues.

This solution is ideal for:

- Carbon fiber wholesalers

- Car modification brands

- Auto tuning shops

- Premium car clubs

If you’re buying in bulk and want to boost customer satisfaction, cut down on after-sales problems, and offer professional-grade parts, our advanced clip-on carbon fiber technology is the upgrade your business needs.

The Problem: Glue-Based Installations Are a Pain

One of our long-term customers—a well-known aftermarket tuning brand—once reached out in frustration:

“We’ve tried carbon fiber parts from other suppliers. The clips break or don’t align, so we have to use glue. Our customers complain about the difficulty of installation and removal. It’s damaging our reputation.”

We’ve heard this many times across the industry. Using glue may seem like a quick fix, but it leads to long-term issues like:

- Poor fitment

- Difficult disassembly

- Higher breakage rates

- Lower customer satisfaction

The JCSPORTLINE Solution: OEM-Level Clip-On Carbon Fiber Parts

We took this challenge seriously and developed a complete clip-based mounting system that works just like OEM parts — but in carbon fiber.

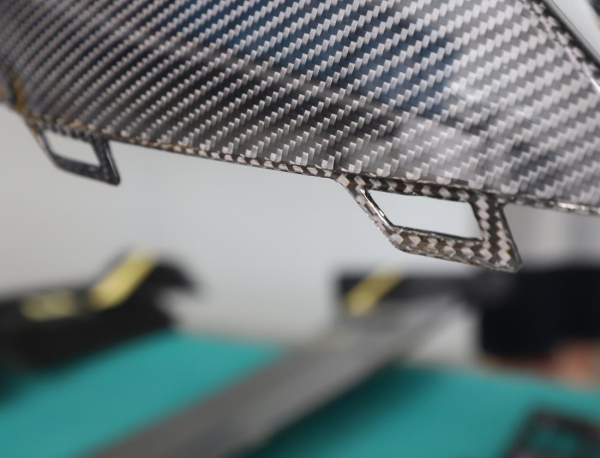

1. Precision Engineering

- High-precision molds for consistent fitment

- CNC cutting to ensure perfect clip shapes and dimensions

2. Material & Structural Optimization

- Smart multi-layered carbon layout for flexibility and strength

- Reinforced clip areas to reduce breakage under pressure

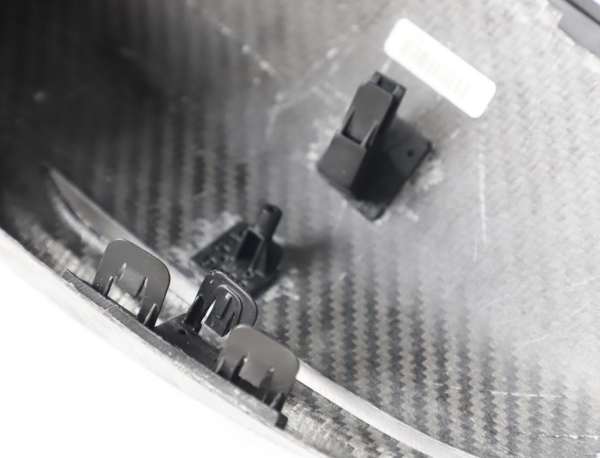

3. Strict Quality Control

- Full inspection from raw material to final product

- Consistent batch quality with intelligent automation

4. Cost-Effective Manufacturing

- Optimized process reduces time and cost

- Mass production spreads cost over larger orders

5. Flawless Fit & Finish

- Tight tolerance control for seamless integration with vehicle body

- Each part is test-fitted on a vehicle before shipping

- Premium coatings for UV protection and long-lasting shine

The Result: Real Feedback From Real Customers

The client adopted our upgraded clip-on carbon fiber parts, and the impact was clear:

- Installation time cut in half

- No glue needed, even for complex shapes

- Stable, noise-free fitment

- Customer complaints dropped by over 80%

Brand reputation and trust improved

“JCSPORTLINE didn’t just give us better parts — they helped us solve a major industry pain point.”

Why It Matters for the Carbon Fiber Aftermarket Industry

As more car owners invest in carbon fiber mods — from spoilers to diffusers to mirror covers — fitment and ease of install are key factors in their purchase decisions. Poor clips or glue-based installs can ruin the ownership experience.

JCSPORTLINE’s solution brings real OEM-level quality to the aftermarket carbon fiber space — and your customers will notice.

Let’s Build Better Carbon Fiber Parts — Together

If you’re tired of dealing with broken clips, messy glue, or unhappy customers, it’s time to level up.

Contact JCSPORTLINE today to learn more about our OEM-style clip carbon fiber parts.

Let’s make high-quality, easy-to-install mods the new standard.