Table of Contents

At JCSPORTLINE, we recently hosted a professional powered-surfboard development team with more than eight years of hands-on experience in both traditional surfboards and electric surfboards. The founders themselves are long-term riders and engineers who design not only the board structure, but also the complete power system together.

This visit once again confirmed a key reality in this niche market: successful powered-surfboard brands are almost always built by people who deeply understand real riding and real operating conditions .

Unlike conventional surfboards, powered surfboards introduce electrical routing, propulsion loads, and local mechanical interfaces. These constraints fundamentally change how carbon fiber structures must be designed and manufactured.

Below we explain how complex powered-surfboard carbon fiber structures should be manufactured—and why OEM brands must clearly understand the difference between autoclave prepreg processes and infusion (wet carbon, vacuum infusion) processes before committing to tooling.

Structural & Process Challenges in Powered Surfboard Carbon Fiber Manufacturing

Powered surfboards are not simply “carbon surfboards with a motor added later.”

The structural concept itself directly dictates which composite processes can realistically be applied.

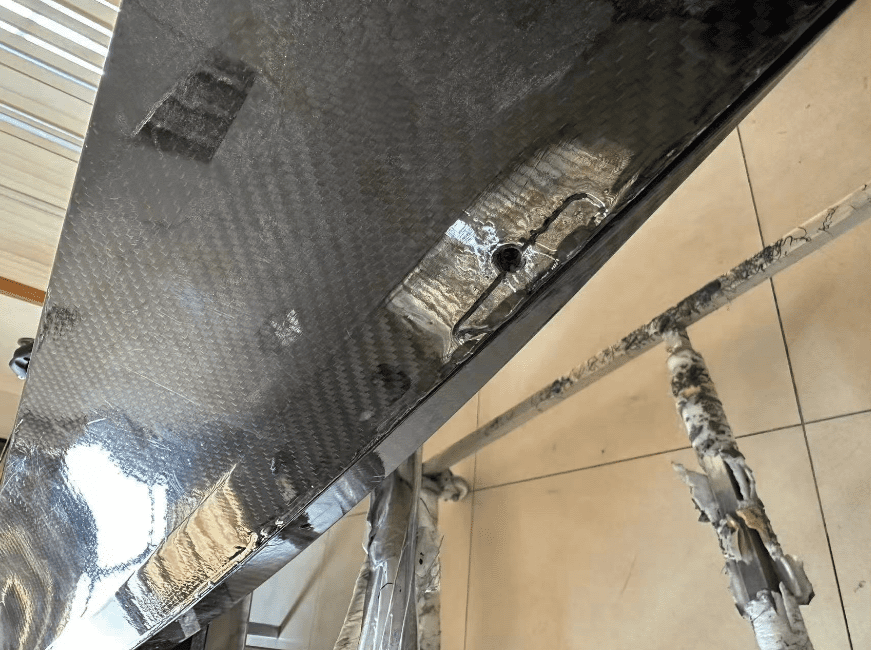

During the factory visit, the customer made it very clear that their board architecture is based on upper and lower shell molding, not a single closed monocoque structure. The reason is straightforward: internal wiring, power system routing and internal components make one-piece molding impractical.

This also means that not all so-called one-piece carbon forming processes are suitable for every powered surfboard design .

Upper and Lower Mold Assembly Constraints

In real powered-surfboard production, the board is typically manufactured as:

- a top shell

- a bottom shell

- followed by assembly and bonding

Because electrical harnesses and internal systems must be routed between shells, a fully closed one-shot molding route is not realistic.

For OEM brands, this creates two critical engineering implications:

- The bonding interfaces between upper and lower shells become load-bearing structures.

- Structural continuity must be carefully designed across the bonding seam.

This is why JCSPORTLINE recommends defining the assembly sequence first, and then designing laminate architecture and insert locations around that sequence.

High-Risk Areas: Sliders, Inserts, and Local Reinforcements

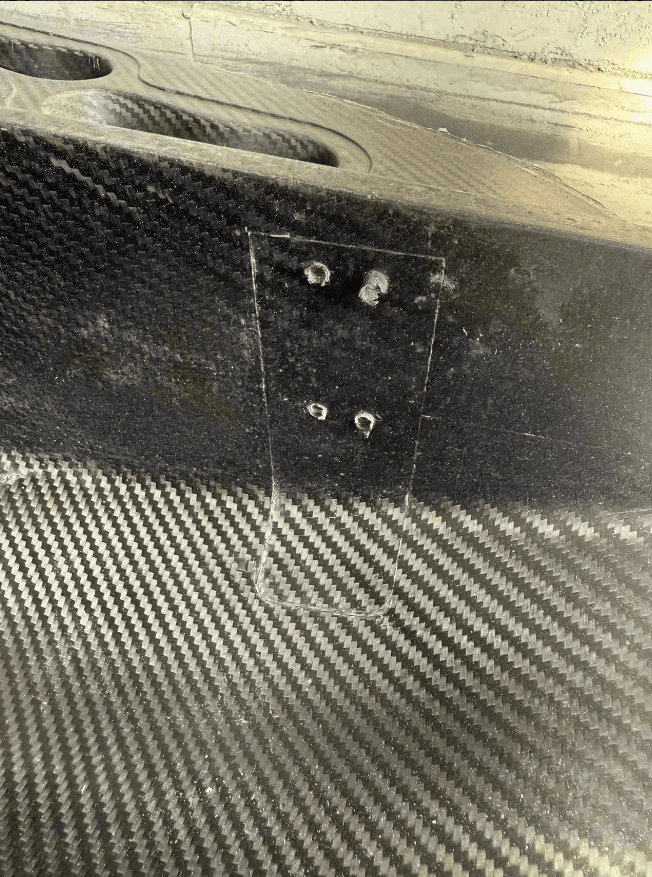

The customer highlighted several structural risk points that frequently cause failures in powered boards.

The most critical is the slider structure area, where local movement and load transfer occur.

This zone is prone to delamination if the laminate is not properly bonded to the embedded parts during layup.

Key engineering controls include:

- special attention to bonding between the laminate and pre-embedded components in slider areas

- avoiding stress concentration at small interface transitions

- maintaining clean bonding surfaces and correct adhesive systems

In addition, embedded screws and inserts must not protrude above the surface and must not sink below the surface. Even a small height deviation can lead to cosmetic defects, sealing issues, and long-term fatigue problems .

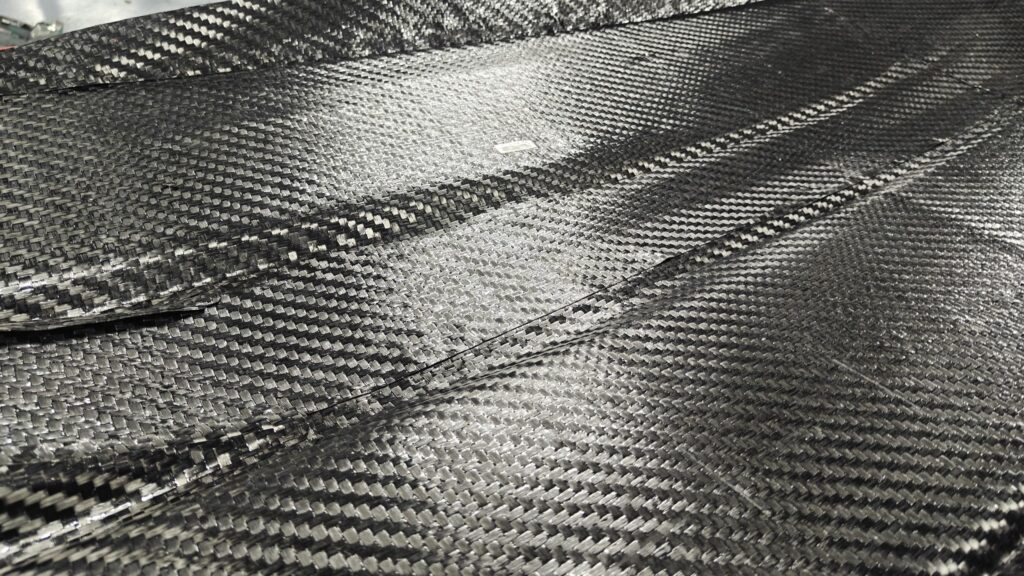

Appearance-Driven Layup Constraints

Premium powered surfboards are highly visual products.

The customer explicitly required:

- no visible carbon fabric splicing

- surfaces should visually appear as if formed from a single continuous piece of fabric

This means:

- carbon fabric should not be joined on visible areas

- layup planning must be driven not only by structural load paths, but also by surface continuity and cosmetic flow

For high-end consumer boards, appearance quality must be designed into the laminate architecture from the beginning, not corrected afterward.

Early Engineering Communication with OEM Teams

One of the most important points raised during the visit was simple but extremely practical:

Any technical uncertainty must be communicated with the customer immediately.

For powered surfboards, this is especially important because:

- mechanical structures

- electronics routing

- and sealing strategies

are highly coupled. Small design changes can cascade into tooling rework or process redesign.

At JCSPORTLINE, we treat early engineering review and continuous OEM communication as a core part of feasibility validation—not as a post-design service.

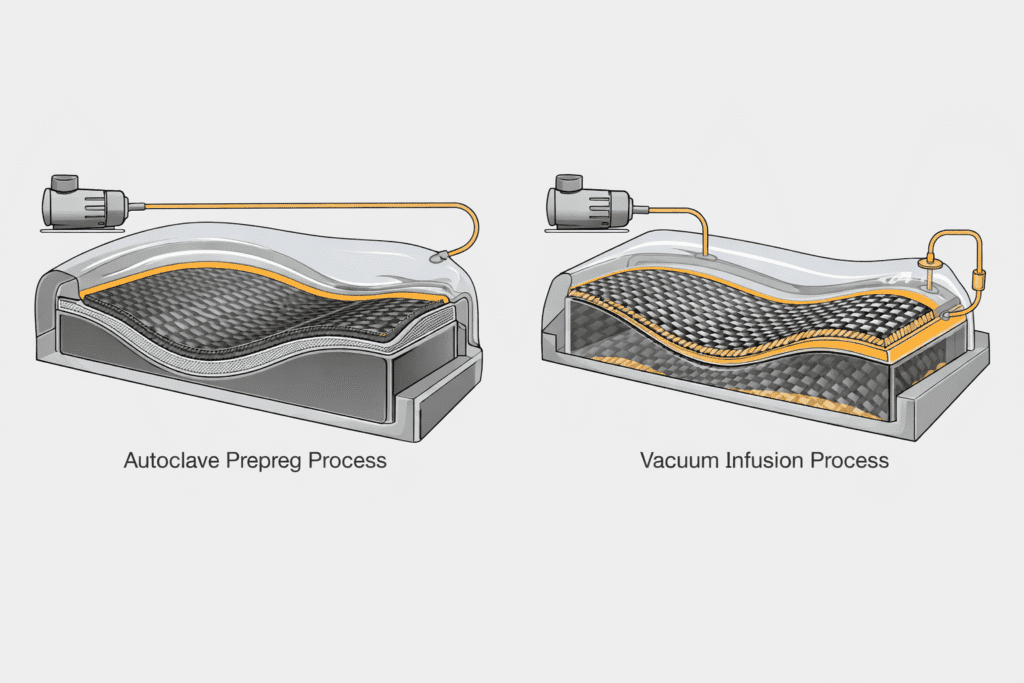

Autoclave vs Infusion for Powered Surfboard Structures

One of the most misunderstood topics in water-sports composites is the difference between infusion processes and autoclave prepreg processes.

During the visit, it was clearly stated that the term infusion refers to the wet-carbon vacuum infusion process widely used in traditional surfboards and marine products—and it should be used as a comparison benchmark against autoclave processing, not confused with prepreg technologies .

What Infusion Is Commonly Used For in Surfboards and Marine Products

Infusion is widely applied in:

- conventional surfboards

- boats and marine structures

- large composite shells where cost and scalability are prioritized

The process relies on:

- dry fiber layup

- vacuum bagging

- resin infusion into the laminate

This approach is very suitable for:

- relatively large structures

- moderate dimensional tolerance requirements

- applications where cosmetic perfection and tight insert tolerances are not critical

For many water-based products, infusion remains a very practical manufacturing route.

Why Autoclave Prepreg Is Better for Complex Powered Structures

Powered surfboards introduce additional complexity:

- local load concentrations from propulsion systems

- multiple embedded inserts

- precision interfaces for moving or removable components

- sealing requirements around electronics

Autoclave prepreg processing offers:

- more stable fiber volume content

- controlled resin distribution

- higher laminate consistency

- better surface quality repeatability

This directly reduces the probability of:

- local dry spots

- inconsistent laminate thickness

- unpredictable bonding behavior around inserts

For complex powered-surfboard structures, especially those integrating mechanical and electrical subsystems, autoclave processing provides a much more controllable manufacturing window.

Tolerance, Insert Positioning, and Assembly Accuracy

The customer explicitly emphasized that:

- embedded screws must remain perfectly flush

- no protrusion

- no sink marks

These requirements become much harder to control in wet-layup and infusion processes when multiple embedded parts are involved.

In autoclave prepreg manufacturing, insert positioning and laminate compaction are more predictable, which significantly improves:

- assembly accuracy

- sealing reliability

- cosmetic stability

Process Selection Strategy for OEM Brands

OEM brands should not select a composite process based solely on industry tradition.

Instead, the decision should be based on:

- structural complexity

- number and type of embedded components

- appearance expectations

- functional tolerance requirements

Infusion remains an excellent solution for traditional boards and marine shells.

Autoclave prepreg becomes a far more suitable solution when powered systems and precision interfaces dominate the design.

Engineering and Quality Control Requirements for OEM Powered Surfboard Programs

During the visit, a detailed production and quality checklist was defined for this powered-surfboard program.

These requirements reflect real-world constraints faced by brands launching premium electric surfboards.

Insert, Fastener, and Titanium Component Integration

For this project:

- titanium components are supplied by the customer

- the piston body is titanium

- welding and cutting of titanium parts are handled by the customer

From a composite engineering standpoint, the critical points are:

- proper bonding compatibility between titanium and carbon laminate

- strict control of insert heights

- avoiding surface distortion around metal interfaces

Additionally, for slider structures:

- pin-type connection designs should be avoided where possible

- chamfers should be introduced to reduce stress concentration and improve assembly stability

Layup Configuration and Material Specifications

The laminate configuration specified during the visit includes:

- three layers of carbon fabric

- black carbon adhesive system

- 3K 2×2 carbon fabric, 200 g

- overall laminate thickness approximately 1.5 mm

From a cosmetic standpoint:

- visible areas must use continuous fabric

- no splicing is allowed

This combination balances:

- surface quality

- structural stiffness

- and visual consistency .

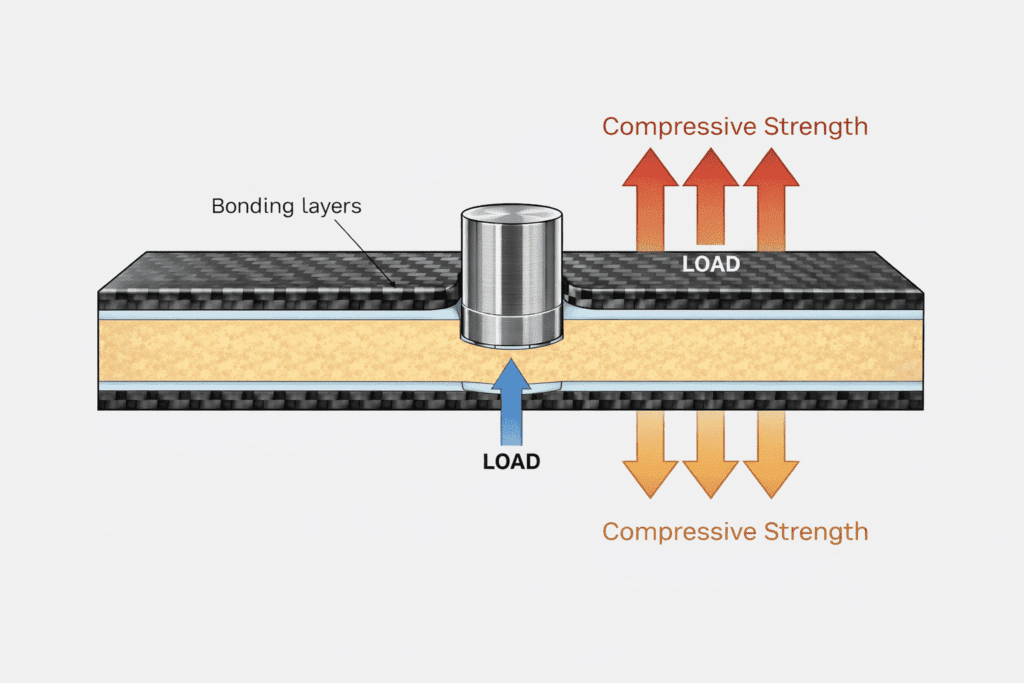

Foam Core Density and Structural Support

The powered-surfboard structure also integrates a foam core layer.

The customer specified:

- foam board integrated at the bottom layer

- required foam density between 45–50

- and an additional reference foam density of 40 for specific areas

Foam density directly influences:

- local compressive strength

- insert pull-out resistance

- long-term bonding stability between shells and reinforcements

Correct foam selection is therefore a structural decision, not simply a weight-saving choice.

Appearance Inspection and Confidentiality Control

Because the customer plans to create marketing materials and technical videos, the inspection and documentation process is tightly controlled.

The agreed requirements include:

- detailed close-up photos and videos

- front and side views must be captured

- focus on structural and cosmetic details

At the same time, strict confidentiality rules apply:

- no real customer surfboard images may be publicly used

- any visible customer faces must be replaced

- technical explanation images should be generated using AI-based illustrative graphics

- real project visuals must not be disclosed

This allows OEM brands to protect product IP while still presenting manufacturing and engineering capability to investors and partners.

FAQ

When should powered surfboards avoid one-piece carbon molding?

When internal wiring, propulsion systems, and mechanical components require access and routing between shells, upper- and lower-shell assembly becomes necessary. In such cases, one-piece molding introduces significant manufacturing and assembly risks.

Is infusion suitable for premium powered surfboards?

Infusion is well suited for conventional surfboards and marine shells. However, when multiple embedded inserts, high cosmetic standards, and tight assembly tolerances are required, autoclave prepreg processing provides significantly better control.

What are the most common structural failure points in powered surfboards?

Based on real production experience, slider areas and insert interfaces are the most frequent sources of delamination and long-term fatigue failures.

How early should OEM brands involve manufacturing engineers?

Manufacturing engineers should be involved before design freeze. Early review helps align laminate architecture, insert design, foam selection, and assembly sequences—preventing costly tooling changes and structural redesign later in the program.