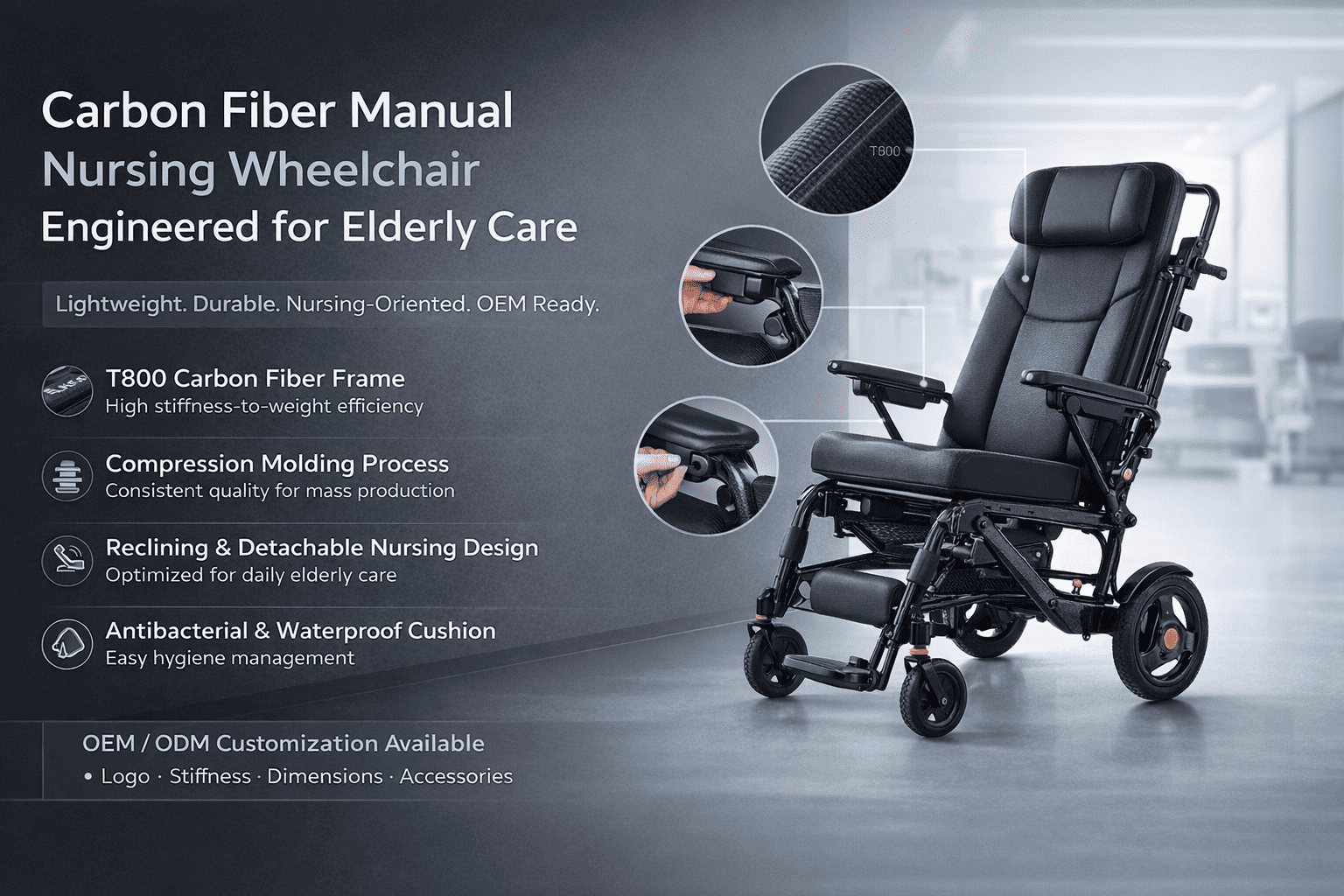

Carbon Fiber Manual Elderly Wheelchair for Nursing Care OEM ODM

Carbon fiber manual nursing wheelchair engineered for elderly care, compression molded structure, OEM/ODM customization supported.

Price: From $129 (Final price depends on customization & OEM requirements)

Leave your contact information, and our consultant will get in touch within 24 hours.

Product Overview

This carbon fiber manual nursing wheelchair is engineered for elderly users requiring assisted mobility and daily care support in home and institutional environments. Designed for OEM brands, medical equipment manufacturers, and healthcare procurement teams, the product balances lightweight structural performance with functional nursing features.

The main frame is manufactured from T800 carbon fiber, providing high stiffness-to-weight efficiency while maintaining long-term structural stability. Compression molding using carbon fiber prepreg and unidirectional layup ensures consistent mechanical properties and repeatable mass production quality. A wear-resistant matte surface coating improves durability in high-frequency care scenarios.

The wheelchair integrates multiple nursing-oriented functions, including a reclining backrest, detachable armrests, height-adjustable footrests, and a dining table interface. Medical-grade sponge cushioning with antibacterial and waterproof treatment enhances hygiene management for elderly care. Solid rubber wheels and stainless-steel hardware are selected to improve reliability and reduce maintenance requirements.

This model is suitable for OEM/ODM programs requiring logo integration, structural stiffness tuning, dimensional adjustment, and accessory expansion, supporting scalable production for home care and institutional nursing markets.

Technical Specifications

| Specification | Description |

|---|---|

| Material | T800 carbon fiber frame; medical sponge seat; solid rubber wheels; stainless steel hardware |

| Fiber Type | Carbon fiber prepreg with unidirectional layers |

| Resin System | Prepreg resin system (not specified) |

| Manufacturing Process | Compression molding |

| Surface Finish | Wear-resistant matte coating |

| Functional Features | Reclining backrest; detachable armrests; adjustable footrests; dining table interface |

| Weight Class | Medium |

| Rolling Resistance | 4 N |

| Brake Response Time | 0.3 s |

| Application | Home nursing care; elderly care institutions |

| Cushion Treatment | Antibacterial and waterproof |

| OEM/ODM Options | Logo customization; stiffness tuning; size adjustment; accessory integration |

Problems We Solve

- Heavy traditional wheelchairs → Carbon fiber structure reduces weight while maintaining rigidity

- Inconsistent product quality in mass production → Compression molding ensures repeatable structural performance

- Limited nursing functionality → Integrated reclining, removable, and adjustable components support daily care needs

- Hygiene management challenges → Antibacterial and waterproof seat cushion treatment

- OEM brand differentiation difficulty → Flexible logo, stiffness, dimension, and accessory customization

Key Advantages

- Carbon fiber engineering capability using prepreg and unidirectional layup design

- Compression molding process suitable for stable batch and mass production

- Nursing-oriented functional integration for elderly care scenarios

- OEM/ODM customization covering structure, dimensions, and accessories

- Material and surface solutions optimized for durability and low maintenance

FAQ

Q1: Is this wheelchair suitable for OEM or private label projects?

Yes. Logo integration, structural stiffness adjustment, size customization, and accessory expansion are supported.

Q2: What manufacturing process is used for the carbon fiber frame?

The frame is produced using compression molding with carbon fiber prepreg materials.

Q3: Is small-batch production available for initial market testing?

OEM/ODM production can be arranged from pilot batches to scaled manufacturing based on project requirements.

Q4: How is hygiene addressed for elderly care use?

The seat cushion uses antibacterial and waterproof treatment to support daily cleaning and infection control.

Q5: What environments is this wheelchair designed for?

It is suitable for home nursing care and professional elderly care institutions.

Q6: Are performance parameters such as rolling resistance and braking tested?

Yes. The wheelchair is specified with 4 N rolling resistance and 0.3 s brake response time for controlled handling.

Industries Served

Medical Devices / Elderly Care Equipment / Home Healthcare / Institutional Nursing Facilities

Sectors: automotive, aerospace/marine, sports, home, medical OEM/ODM available; build to drawings/samples

Yes. With 20 years of experience, we offer customization for color, style, and dimensions, and can build to customer drawings or samples (OEM/ODM).

Incoming material hardness/performance checks; Key processes: vacuum bagging, thermal curing, wet sanding & polishing; Paint hardness testing and final quality inspection (FQC) before shipment.

Depends on the product. For single components like spoilers, the typical MOQ is 5–10 pcs; final MOQ is negotiable by vehicle model and design.

Yes. We can apply customer logos, provide OEM packaging, and deliver tailor-made design solutions.

FBA direct fulfillment and global warehousing; Protective packaging for safe transport; Courier, air freight, or sea freight arranged per customer request.

We offer a return and exchange policy for quality issues.

Our technical support team is always available to answer any questions regarding installation, maintenance, and upkeep.

Business-to-business customers can enjoy long-term partnership discounts and regular product previews.