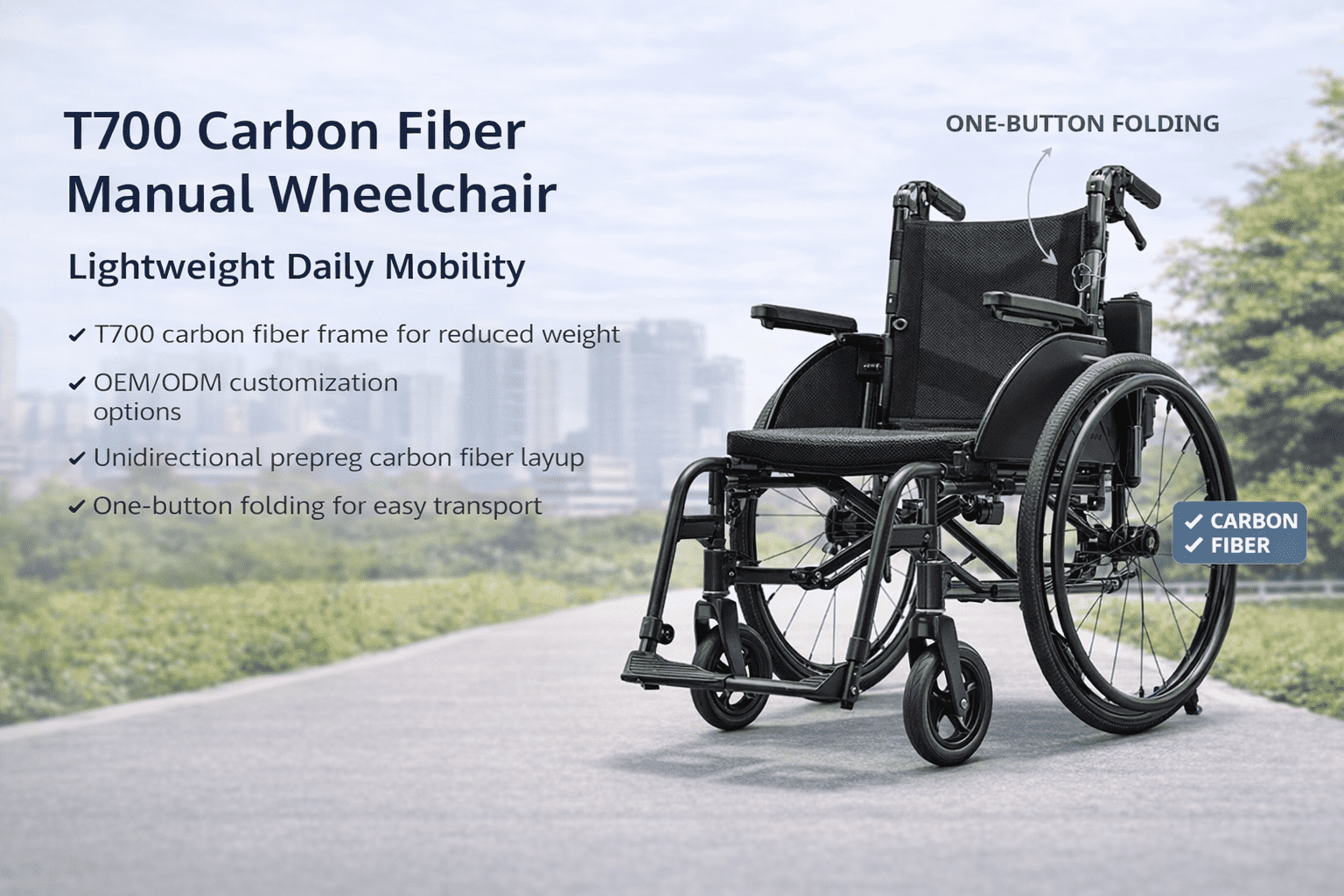

T700 Carbon Fiber Manual Wheelchair for Lightweight Daily Mobility

This lightweight manual wheelchair is engineered using a T700 carbon fiber structural frame to reduce overall mass while maintaining sufficient rigidity for daily assisted mobility. Designed as a basic folding configuration, it targets OEM brands and medical equipment suppliers seeking a portable, entry-level carbon fiber wheelchair platform.

Price: From $129 (Final price depends on customization & OEM requirements)

Leave your contact information, and our consultant will get in touch within 24 hours.

Product Overview

The frame is manufactured through compression molding with unidirectional carbon fiber prepreg layup, ensuring stable fiber orientation and repeatable mechanical performance. A matte clear coat surface finish protects the composite structure while maintaining a clean, technical appearance suitable for medical and mobility applications.

The wheelchair integrates a one-button folding mechanism for fast storage and transport, combined with fixed armrests and a simplified footrest structure to minimize component complexity and maintenance requirements. Breathable mesh fabric is used for the seat to improve sitting comfort during short-distance use.

With low rolling resistance (3N push force) and a folding time of approximately 10 seconds, this model is optimized for indoor movement and short outdoor trips such as supermarkets, parks, and residential environments. OEM/ODM customization is available for branding, stiffness tuning, and seat width dimensions.

Technical Specifications

| Specification | Description |

|---|---|

| Product Type | Manual carbon fiber wheelchair |

| Frame Material | T700 carbon fiber |

| Seat Material | Breathable mesh fabric |

| Front Wheels | PU wheels |

| Rear Wheels | Rubber wheels |

| Layup Structure | Unidirectional carbon fiber prepreg |

| Surface Finish | Matte clear coat |

| Manufacturing Process | Compression molding |

| Folding Structure | One-button folding mechanism |

| Armrest | Fixed |

| Footrest | Simplified structure |

| Push Resistance | 3 N |

| Folding Time | Approx. 10 seconds |

| Surface Treatment | Carbon fiber: matte clear coat; Metal parts: zinc-plated anti-rust |

| Customization Options | Logo, stiffness, seat width |

| Application Scenarios | Indoor use, short-distance outdoor travel |

Problems We Solve (Pain Point → Solution)

-

Excessive wheelchair weight → Carbon fiber frame significantly reduces mass while maintaining structural rigidity

-

Inconsistent folding mechanisms → Integrated one-button folding design with repeatable motion control

-

High rolling resistance → Optimized wheel selection achieving 3N push resistance

-

Limited OEM differentiation → Customizable stiffness, seat width, and branding

-

Surface durability issues → Matte clear coat and zinc-plated hardware for corrosion resistance

Key Advantages (Why Choose Us)

-

Carbon fiber structural engineering with unidirectional prepreg layup control

-

Compression molding process for dimensional consistency and batch repeatability

-

OEM/ODM flexibility from basic configuration to parameter-level customization

-

Production-ready design suitable for low-volume and scaled manufacturing

-

Quality-controlled surface finishing for medical and mobility environments

FAQ

Q1: Can this wheelchair be customized for different seat widths?

Yes. Seat width customization is supported under OEM/ODM programs.

Q2: Is this model suitable for long-distance outdoor use?

It is designed primarily for indoor use and short-distance outdoor travel.

Q3: What manufacturing process is used for the frame?

The frame is produced using compression molding with unidirectional carbon fiber prepreg.

Q4: Can stiffness be adjusted for different user requirements?

Yes. Frame stiffness can be tuned during the layup design stage.

Q5: What surface protection is applied to metal components?

Metal parts are zinc-plated for corrosion resistance.

Q6: Is logo customization available?

Yes. Logo customization is available for OEM branding projects.

Sectors: automotive, aerospace/marine, sports, home, medical OEM/ODM available; build to drawings/samples

Yes. With 20 years of experience, we offer customization for color, style, and dimensions, and can build to customer drawings or samples (OEM/ODM).

Incoming material hardness/performance checks; Key processes: vacuum bagging, thermal curing, wet sanding & polishing; Paint hardness testing and final quality inspection (FQC) before shipment.

Depends on the product. For single components like spoilers, the typical MOQ is 5–10 pcs; final MOQ is negotiable by vehicle model and design.

Yes. We can apply customer logos, provide OEM packaging, and deliver tailor-made design solutions.

FBA direct fulfillment and global warehousing; Protective packaging for safe transport; Courier, air freight, or sea freight arranged per customer request.

We offer a return and exchange policy for quality issues.

Our technical support team is always available to answer any questions regarding installation, maintenance, and upkeep.

Business-to-business customers can enjoy long-term partnership discounts and regular product previews.