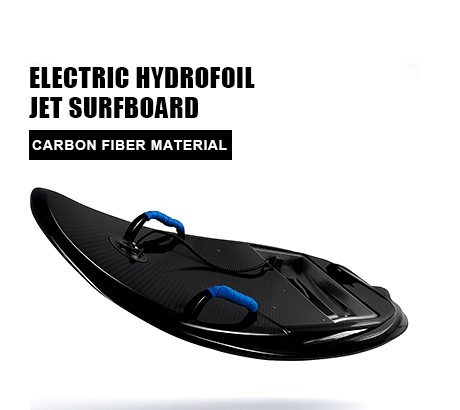

Carbon Fiber Electric Hydrofoil Jet Surfboard — High-Speed Stand-Up E-Foil Board

Price: From $129 (Final price depends on customization & OEM requirements)

Leave your contact information, and our consultant will get in touch within 24 hours.

Product Description – High-Speed Stand-Up E-Foil Board

Experience a new era of water performance with our Carbon Fiber Electric Hydrofoil Jet Surfboard.

This high-speed stand-up E-Foil board integrates advanced jet propulsion, hydrofoil lift, and aerospace-grade carbon fiber construction to deliver an unmatched combination of power, balance, and agility. Designed for both professionals and water sport enthusiasts, it offers the sensation of flying above the water — with smooth acceleration, stable lift, and effortless control.

Key Features

- Carbon Fiber Composite Structure – Constructed using aerospace-grade prepreg carbon fiber for exceptional strength, lightweight performance, and saltwater resistance.

- Jet Propulsion + Hydrofoil Lift – Dual propulsion concept combining jet thrust with hydrofoil dynamics for seamless gliding and high-speed flight.

- High-Speed Performance – Achieves up to 55 km/h with instant torque, low drag, and controlled lift-off from CFD-optimized design.

- One-Piece Compression Molding – Ensures a perfectly smooth carbon surface without seam lines for superior rigidity and hydrodynamics.

- Smart Power System – IP68-rated lithium battery module with intelligent BMS safety protection and easy plug-in design for fast swaps.

- Customizable Finishes – Available in gloss, matte, forged, or color-tinted carbon with optional OEM logo and branding integration.

Customer Problems We Solve

- High Drag & Energy Waste – Traditional electric boards consume more power at speed. Our fix: CFD-engineered hydrofoil lift reduces drag by up to 35%, extending runtime.

- Weak Seams & Water Leaks – Hand-layup boards often separate under load. Our fix: one-piece compression molding eliminates seams and improves durability.

- Vibration & Instability – Inconsistent foil geometry causes shaking. Our fix: precisely tuned carbon fuselage and mast ensure smooth, predictable control.

- Heavy, Unbalanced Boards – Fiberglass structures exceed 20 kg. Our fix: carbon + core sandwich reduces total weight to ~9 kg for easier handling and transport.

- Corrosion & Fatigue in Marine Conditions – Saltwater damages unprotected hardware. Our fix: marine-grade 316L stainless inserts and sealed components guarantee long service life.

Why Choose a Carbon Fiber E-Foil Jet Board?

- Lift + Jet Synergy – Hydrofoil lift minimizes drag while the jet drive maintains consistent thrust for stable, efficient gliding.

- Lightweight & Responsive – Carbon fiber rigidity enhances power transfer and control without unnecessary mass.

- Eco-Friendly Propulsion – Electric jet technology delivers zero emissions and near-silent operation on any body of water.

- Luxury Aesthetics – Seamless exposed carbon weave finish conveys a premium, high-performance identity.

- Durability for Professional Use – Built to withstand UV, impact, and saltwater conditions across repeated sessions.

Applications

- Professional riders and e-foil racers demanding high-performance precision control.

- Luxury resorts, clubs, and yacht operators providing exclusive hydrofoil experiences.

- OEM/ODM partners developing private-label electric surfboard lines.

- Training centers and recreational users exploring stable, safe, and exciting water flight.

Frequently Asked Questions (FAQ)

Q1: What’s the top speed and battery runtime?

A1: The board reaches up to 55 km/h and runs for 80–90 minutes per charge, depending on rider weight and water conditions.

Q2: Is the hydrofoil detachable?

A2: Yes. The mast and foil system are modular and can be detached for transportation or replacement.

Q3: Can I customize the design for my brand?

A3: Absolutely. OEM/ODM customization is available for board shape, finish, logo, and foil specifications.

Q4: Is it safe for saltwater environments?

A4: Yes. All mechanical and electrical components are IP68 sealed and use 316L stainless steel for corrosion resistance.

Q5: What kind of maintenance is required?

A5: Minimal — rinse with fresh water after each use and store in a dry, shaded environment. The modular jet and foil system make servicing easy.

Ride above the surface with JCSPORTLINE — where electric innovation meets carbon fiber performance.

Design Phase: From Hydrodynamics to Structural Optimization

- SolidWorks / CATIA with CFD hydrodynamic simulation for complete structural design.

- Optimized waterline, tail rocker, and channel layout for lower drag and higher agility.

- V-shape or dual-concave bottom with leading-edge radius control for stability in choppy water.

- Integrated inserts & routing during design to minimize post-processing risk and leakage points.

- AI-based load & CG simulation ensures stability at speed across multiple sea conditions.

Lightweight Structure: Achieving the 8 KG Balance

- Sandwich Construction: “Carbon Fiber + Core” for strength-to-weight efficiency.

- Carbon Layers: 2×2 twill outer (impact) + unidirectional inner (longitudinal) with ±45° lay-up for torsional rigidity.

- Core Material: PU or PMI foam (60–120 kg/m³); PU offers PMI-like mechanics at lower cost.

- Localized Reinforcement: Tail, stance zone, and fin base per use case (racing/rental/recreation).

Weight Performance: Mainstream target ≈ 8 kg, tuned per strength standard while maintaining buoyancy and stability.

Mold Manufacturing: Precision from Surface to Structure

- P20 mold steel with Ra ≤ 0.8 μm mirror finish.

- 5-axis CNC machining for ±0.1 mm tolerance.

- Split mold + precision locating pins for exact alignment.

- Teflon release layer prevents fiber print-through and surface damage during demolding.

- One-piece compression molding eliminates visible seams; continuous carbon weave increases strength by ~35%.

Prototyping and Performance Validation

- Thermal Curing: 120 °C autoclave for 4h or 150 °C press-molding for 1.5h.

- Mechanical Testing: Flexural ≥300 MPa; Tensile ≥80 MPa; Core shear ≥15 MPa.

- Dynamic Testing: Water-tank tuning places the CG at ~1/3 board length for optimal control.

- 3D Scan Verification: CAD vs. prototype deviation ≤0.5 mm for repeatable precision.

Appearance and Coating

- Seamless one-piece surface with continuous carbon weave.

- Finishes: Gloss / Matte / Semi-transparent Carbon / Custom Logo.

- Large water-decal capability (>1 m) for branding.

- All finishes pass thermal cycling and salt-spray tests—no peeling, blistering, or warping.

Waterproofing and Anti-Corrosion Design

- Marine-grade stainless steel 316L inserts and hardware.

- 24-hour salt-spray pre-treatment; service life ≥ 3 years in marine conditions.

- Glass-fiber wrap + ABS reinforcement around insert zones to resist fatigue.

Mass Production and Quality Control

- Automated prepreg cutting, accuracy ±0.2 mm.

- PU core one-shot molding for uniform density.

- 150 °C / 90 min compression molding with closed-loop temperature monitoring.

- Ultrasonic (UT) + industrial CT; internal defect rate ≤0.5%.

- Modular assembly design; efficiency +60%.

- Custom PE film + foam crate; transport vibration ≤2g.

Environmental and Sustainable Manufacturing

- ≥90% carbon fiber recycling via fiber carbonization.

- Solar-powered curing reduces unit energy by ~30%.

- Low-VOC resin systems to minimize emissions.

Key Technical Challenges and Solutions

| Technical Challenge | JCSportline Solution |

|---|---|

| Interlaminar Delamination | Glass-fiber transition layers to increase interfacial bonding strength. |

| Mold Deformation | P20 steel mold with constant-temperature control; lifespan ≥ 5000 cycles. |

| Batch Consistency | Digital monitoring of curing pressure and temperature; automated adjustments. |

| Visible Seam Lines | One-piece compression molding eliminates joint lines entirely. |

Final Performance Summary

- Weight: 8–15 kg, tunable via lay-up per strength target (mainstream target ≈ 8 kg).

- Dynamic Load Capacity: ≥ 500 kg.

- Surface Texture: Seamless carbon weave, natural flow without seam lines.

- Waterproof Durability: ≥ 3 years in marine conditions.

- Finish Quality: Mirror-like gloss or matte; no color deviation or bubbles.

Our Carbon Fiber Electric Surfboard achieves an optimal balance of innovation, performance, and durability.

With aerospace-grade materials, one-piece compression molding, and CFD-guided design, it delivers a precise, stable, and premium riding platform—

whether you are chasing performance or curating a dependable fleet for rental operations. Propulsion system is not included.

Sectors: automotive, aerospace/marine, sports, home, medical OEM/ODM available; build to drawings/samples

Yes. With 20 years of experience, we offer customization for color, style, and dimensions, and can build to customer drawings or samples (OEM/ODM).

Incoming material hardness/performance checks; Key processes: vacuum bagging, thermal curing, wet sanding & polishing; Paint hardness testing and final quality inspection (FQC) before shipment.

Depends on the product. For single components like spoilers, the typical MOQ is 5–10 pcs; final MOQ is negotiable by vehicle model and design.

Yes. We can apply customer logos, provide OEM packaging, and deliver tailor-made design solutions.

FBA direct fulfillment and global warehousing; Protective packaging for safe transport; Courier, air freight, or sea freight arranged per customer request.

We offer a return and exchange policy for quality issues.

Our technical support team is always available to answer any questions regarding installation, maintenance, and upkeep.

Business-to-business customers can enjoy long-term partnership discounts and regular product previews.