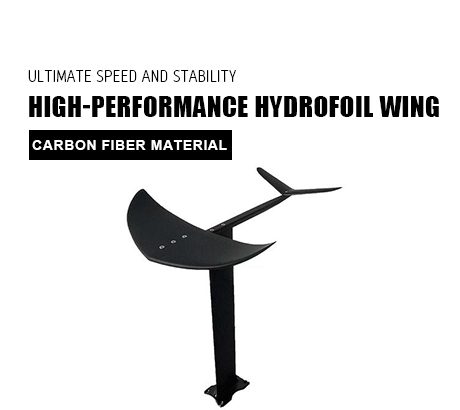

High-Performance Carbon Fiber Hydrofoil Wing for Ultimate Speed and Stability

Price: From $129 (Final price depends on customization & OEM requirements)

Leave your contact information, and our consultant will get in touch within 24 hours.

High-Performance Carbon Fiber Hydrofoil Wing for Ultimate Speed and Stability

Experience the next evolution of hydrodynamic performance with our Carbon Fiber Hydrofoil Wing — designed for riders who demand precision, lift, and speed on water.

Crafted from aerospace-grade carbon fiber and refined through CFD (Computational Fluid Dynamics) optimization, this hydrofoil wing delivers unmatched glide efficiency, ultra-light responsiveness, and rock-solid stability across all conditions. Whether for e-foils, surf foils, or kiteboards, it redefines performance beneath the surface.

Key Features

Aerospace-Grade Carbon Fiber Construction – Ultra-light, high-strength monocoque structure for optimal stiffness and corrosion resistance.

Hydrodynamic Wing Geometry – CFD-optimized profile ensures maximum lift-to-drag ratio and stable pitch control.

Modular Connection System – Precision CNC aluminum fuselage interface allows quick assembly and interchangeability.

Tapered Wing Tips – Reduces cavitation and turbulence for smoother carving and higher top-end speed.

Seamless One-Piece Molding – Continuous carbon weave with no joint lines improves structural integrity and water flow.

Custom Finish Options – Choose gloss, matte, forged, or semi-transparent carbon with personalized branding.

Customer Problems We Solve

Instability & Drag – Traditional foils cause wobbling and inefficiency.

✅ Our fix: CFD-driven airfoil geometry and low-drag wing section for balanced, stable lift.

Weight & Fatigue – Aluminum or fiberglass foils add mass and flex under load.

✅ Our fix: Full carbon layup (2×2 twill + UD reinforcement) achieves exceptional stiffness-to-weight ratio.

Vibration & Noise – Poor lamination or assembly creates chatter at high speed.

✅ Our fix: Precision compression molding and anti-resonance design reduce hydrodynamic vibration.

Corrosion & Wear – Saltwater damages standard hardware.

✅ Our fix: 316L marine-grade inserts and UV-protected coatings for long-term durability.

Why Choose Carbon Fiber?

-

Superior Strength-to-Weight Ratio – Lightweight carbon structure for explosive lift and agile control.

-

Precision Engineering – CNC-machined molds with ±0.1 mm accuracy guarantee consistent wing profiles.

-

Performance Stability – Carbon stiffness maintains lift and feedback even under high loads.

-

Luxury Finish – Exposed weave pattern symbolizes craftsmanship and performance prestige.

-

Extended Lifespan – Resistant to fatigue, UV, and saltwater degradation for years of professional use.

Applications

-

Electric foils (E-Foils) seeking higher lift and speed efficiency.

-

Surf and SUP foiling enthusiasts pursuing smooth, long glides.

-

Kiteboard and windfoil setups requiring modular precision systems.

-

OEM/ODM partners developing branded carbon foil product lines.

Frequently Asked Questions (FAQ)

Q1: What speed range does it support?

A1: Designed for 15–50 km/h operation depending on board, rider, and wing configuration.

Q2: Is it compatible with my current fuselage and mast?

A2: Yes, the modular mount system supports most standard 4-bolt and plate-style connections.

Q3: Can it be used in saltwater?

A3: Absolutely. All components are marine-rated and corrosion-resistant.

Q4: Do you offer customization?

A4: Yes. OEM/ODM customization available for size, finish, logo, and hydrodynamic tuning.

Q5: How durable is the wing?

A5: Tested for flexural strength ≥300 MPa and fatigue life exceeding 500,000 cycles.

Engineering Excellence: From Simulation to Sea

-

CFD-Optimized Wing Design – Refined lift curve and pressure distribution for smoother takeoff and efficient cruising.

-

Finite Element Analysis (FEA) – Simulated load paths ensure zero structural failure under dynamic forces.

-

Compression Molding Process – 150°C / 90 min cure cycle ensures uniform resin distribution and superior bonding.

-

Core Structure – High-density PMI foam (60–120 kg/m³) core with localized reinforcement at load zones.

-

Surface Finish – Mirror-grade carbon weave, polished to aerodynamic perfection.

Mass Production & Quality Assurance

-

Automated prepreg cutting with ±0.2 mm precision.

-

Controlled autoclave curing for consistent fiber alignment.

-

Ultrasonic (UT) + industrial CT inspection for internal voids (<0.5%).

-

Surface finish verified under ISO 2813 gloss standards.

-

100% waterproof and UV-stable coating for marine longevity.

Sustainability & Innovation

-

≥90% carbon fiber recycling from offcut reclaim process.

-

Low-VOC resin system reduces emissions during curing.

-

Solar-powered production facility with digital curing monitoring.

Final Performance Summary

| Property | Specification |

|---|---|

| Weight | 1.2–1.8 kg (per front wing, depending on size) |

| Material | Full 3K carbon fiber + PMI core |

| Load Capacity | ≥ 400 kg dynamic |

| Surface Finish | Gloss / Matte / Forged Carbon |

| Lifespan | ≥ 3 years marine use |

| Design Accuracy | ±0.1 mm tolerance |

Sectors: automotive, aerospace/marine, sports, home, medical OEM/ODM available; build to drawings/samples

Yes. With 20 years of experience, we offer customization for color, style, and dimensions, and can build to customer drawings or samples (OEM/ODM).

Incoming material hardness/performance checks; Key processes: vacuum bagging, thermal curing, wet sanding & polishing; Paint hardness testing and final quality inspection (FQC) before shipment.

Depends on the product. For single components like spoilers, the typical MOQ is 5–10 pcs; final MOQ is negotiable by vehicle model and design.

Yes. We can apply customer logos, provide OEM packaging, and deliver tailor-made design solutions.

FBA direct fulfillment and global warehousing; Protective packaging for safe transport; Courier, air freight, or sea freight arranged per customer request.

We offer a return and exchange policy for quality issues.

Our technical support team is always available to answer any questions regarding installation, maintenance, and upkeep.

Business-to-business customers can enjoy long-term partnership discounts and regular product previews.