Table of Contents

The Challenges of Carbon Fiber Custom Design: Why Precision Matters

Reverse Engineering vs. Traditional Handcrafted Methods: What’s the Difference?

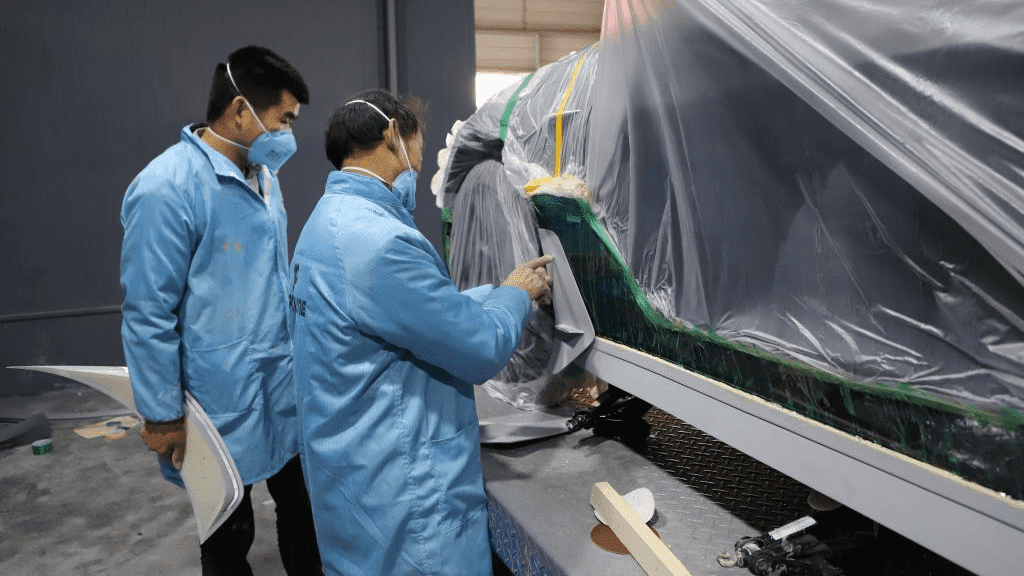

Carbon fiber customization isn’t just about making things look good—it’s about ensuring the components perform at their best while fitting perfectly on the vehicle. Two common approaches to carbon fiber design are reverse engineering and traditional handcrafted methods. In this section, we’ll compare the two to highlight how reverse engineering provides superior fitment, accuracy, and performance optimization.

🔘 Get Your Personalized Quote Now

🔘 Get Your Aerodynamic Upgrade Plan

Comparison of Reverse Engineering and Traditional Handcrafted Methods:

- Precision and Fitment:

- Reverse Engineering: Reverse engineering, with the aid of 3D scanning and digital data analysis, captures the exact measurements and shape of the vehicle’s original parts. This data is then used to create custom parts that fit the car perfectly. With reverse engineering, every detail is captured with accuracy to ensure seamless installation without gaps or misalignments. The digital approach ensures that the final product is an exact replica of the intended design, ensuring a superior fit that minimizes any installation issues.

- Traditional Handcrafted Methods: Handcrafted methods, while valuable in producing bespoke designs, are often based on measurements made by hand or trial and error. This approach lacks the precision of digital tools, leading to potential inconsistencies in measurements and fitment. Handcrafted parts might require several iterations to achieve the right fit, resulting in a longer production time and sometimes suboptimal installation precision.

- Time Efficiency:

- Reverse Engineering: With reverse engineering, once the 3D scan data is captured, the design process becomes quicker and more efficient. The data can be easily adjusted, and prototypes can be tested digitally before any physical models are created. This reduces the need for multiple iterations and speeds up the time to production.

- Traditional Handcrafted Methods: Creating carbon fiber parts by hand requires more time-consuming adjustments and refinements. Each new design may require re-measuring and remaking prototypes, which increases the overall lead time. This traditional approach is less efficient in terms of time, especially when compared to the streamlined process enabled by reverse engineering.

- Performance Optimization:

- Reverse Engineering: Reverse engineering allows for not just precise fitment but also performance optimization. By analyzing the structure of existing parts, we can make adjustments to improve aerodynamics, reduce drag, and enhance vehicle stability. Using 3D data, engineers can identify areas where the design can be improved, resulting in better performance without compromising the vehicle’s original look.

- Traditional Handcrafted Methods: Traditional handcrafting methods don’t have the same performance optimization capabilities. Adjustments are often based on physical testing and experience, which might overlook subtle but crucial factors such as aerodynamics or weight distribution. As a result, handcrafted parts may not always achieve the same performance gains that reverse-engineered parts can.

For example, we once worked with a customer who wanted to fit a custom carbon fiber body kit onto their modified sports car. The vehicle had undergone extensive changes, and traditional methods would have required several prototype adjustments before achieving a proper fit. However, we utilized reverse engineering to capture the vehicle’s exact dimensions using 3D scanning. With the precision data, we were able to design a perfectly fitting carbon fiber kit on the first attempt. The client was thrilled not only with the flawless fitment but also with the enhanced aerodynamics that improved the car’s performance, showcasing how reverse engineering provides both installation precision and performance benefits.

The Hidden Costs Behind Free Design: The Truth You Need to Know

The Real Cost Behind Free Design

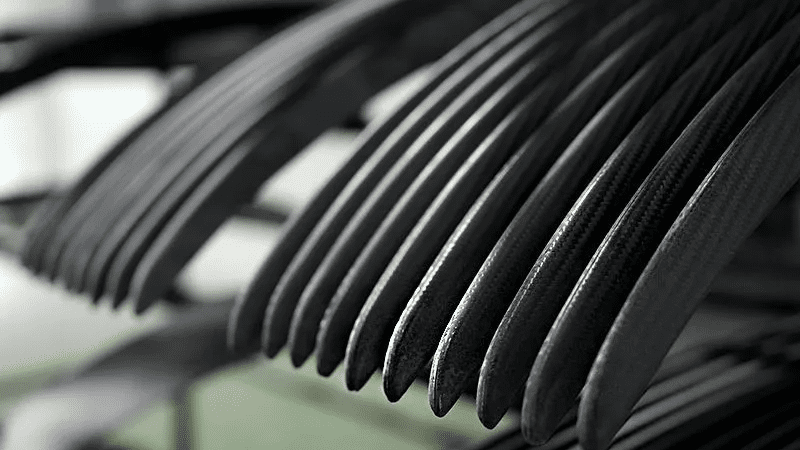

While free design services might seem like a great deal, the true value lies in the technology and expertise behind the design process. At JCSPORTLINE, we don’t just offer free initial designs; we ensure every design undergoes rigorous research, testing, and material validation to ensure product performance and quality. Rather than relying on free designs, we recommend choosing a comprehensive service that includes full technical support, avoiding future issues caused by design flaws.

Why JCSPORTLINE Is the Best Choice for Your Custom Carbon Fiber Needs

Our Professional R&D Team Drives Excellence in Design

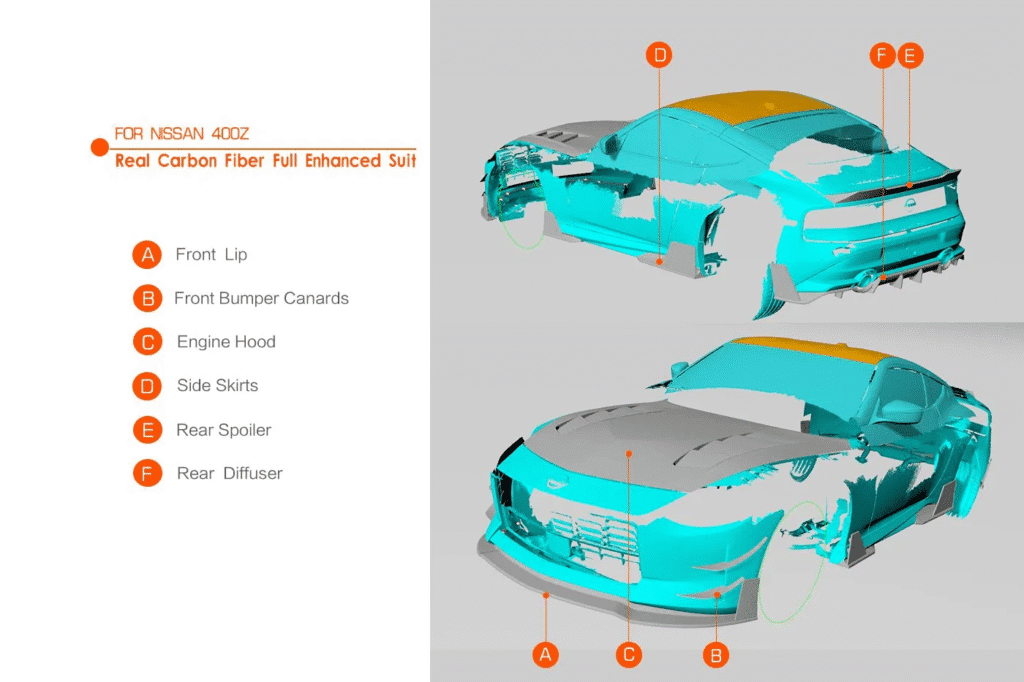

JCSPORTLINE is not just a carbon fiber customization manufacturer; we have a powerful R&D team with extensive technical expertise. Using cutting-edge 3D scan data and reverse engineering techniques, we ensure that every custom product meets strict performance standards and satisfies your high customization needs.

A renowned racing modification company approached us to customize a batch of carbon fiber body kits. Given the unique requirements for their race cars, our R&D team quickly responded, using 3D scanning and reverse engineering to ensure perfect fitment for each part. Throughout the process, we not only focused on design details but also optimized the product’s performance, ultimately enhancing the car’s aerodynamics. As a result, the modified race cars gained a competitive edge in racing events, and the client was extremely satisfied with the products’ performance. They praised our R&D team for their technical expertise and innovation, and expressed interest in future collaborations.

FAQ

Q1: Why does JCSPORTLINE’s custom service require reverse engineering?

- Answer: Reverse engineering helps us capture and analyze precise data from existing parts, ensuring that every custom product perfectly fits your vehicle and enhances its performance. It’s a crucial step in achieving high-quality, custom design.

Q2: How does reverse engineering enhance the performance of JCSPORTLINE’s carbon fiber products?

- Answer: Reverse engineering allows us to precisely recreate a vehicle’s structure, enabling us to optimize carbon fiber parts for better aerodynamics, reduced drag, and increased vehicle stability, improving overall performance.

Q3: What makes JCSPORTLINE’s reverse engineering different from traditional handcrafting?

- Answer: JCSPORTLINE’s reverse engineering combines the latest 3D scanning technology with a professional design team, ensuring every detail is meticulously calculated and adjusted. We focus not only on aesthetics but also on the functionality and performance of every custom component, ensuring an exceptional experience for our clients.