Table of Contents

Understand What Makes Your JCSPORTLINE Carbon Fiber Surfboard Different

When it comes to high-performance surfboards, the JCSPORTLINE carbon fiber surfboard stands out due to its cutting-edge construction techniques and meticulous attention to detail. Understanding the advanced processes behind its creation not only highlights its superiority but also underscores why proper maintenance is essential for preserving its performance and longevity.

Aerospace-Grade Lay-Up: Precision in Every Layer

The foundation of a JCSPORTLINE carbon fiber surfboard lies in its aerospace-grade lay-up process. This involves carefully layering pre-cut carbon fiber sheets onto molds at specific angles, ensuring optimal strength and flexibility. Each layer is meticulously aligned with core materials and reinforcement structures to create a lightweight yet robust composite.

This precision-based approach ensures that every surfboard meets exacting standards for durability and performance. By understanding this process, surfers can appreciate why even minor impacts or improper handling can compromise the structural integrity of their board.

120°C Autoclave Cure: Unlocking Maximum Strength

Once the layers are set, the surfboard undergoes a high-temperature curing process inside an autoclave. At temperatures reaching 120°C, the epoxy resin fully cures under controlled pressure, enhancing the bonding between carbon fibers and core materials. For certain components, additional compression molding at 150°C further refines the structure.

This rigorous curing method eliminates air bubbles and imperfections, resulting in a seamless finish and unparalleled strength. It’s one of the key reasons why JCSPORTLINE surfboards excel in terms of carbon fiber surfboard durability. Surfers who invest in these boards benefit from a product designed to withstand the rigors of both casual rides and competitive waves.

3D Scanning for Unmatched Accuracy

To ensure absolute precision, JCSPORTLINE employs 3D scanning technology during prototyping and production. This advanced technique compares each prototype against the original design model, identifying any deviations exceeding 0.5mm. If discrepancies are found, adjustments are made to refine the mold before final manufacturing begins.

Such stringent tolerances guarantee that every surfboard adheres to the intended specifications, delivering consistent performance across all units. Knowing this level of detail goes into your surfboard reinforces the importance of treating it as a finely tuned piece of equipment.

Why Gentle Maintenance Matters

Given the sophisticated engineering behind JCSPORTLINE surfboards, maintaining them requires a gentle touch. The combination of aerospace-grade lay-ups, high-temperature curing, and precise 3D scanning results in a surfboard that demands respect. Regular cleaning, avoiding harsh chemicals, and storing it away from direct sunlight will help preserve its pristine condition and extend its lifespan.

By appreciating the craftsmanship involved in creating your JCSPORTLINE surfboard, you’ll be better equipped to care for it properly—ensuring many seasons of thrilling rides ahead.

Daily & Post-Session Care: 5 Minutes That Add 5 Years

Proper care of your JCSPORTLINE carbon surfboard can significantly extend its lifespan while maintaining showroom-level performance. With just five minutes of attention after each session, you can protect your investment and enjoy years of reliable use. Here’s how to keep your surfboard in top condition with simple yet effective practices.

Fresh-Water Rinse & Salt Removal (Focus on IPX7 Seals)

Saltwater is one of the biggest enemies of any surfboard, especially high-performance carbon fiber models like those from JCSPORTLINE. When salt dries, it forms crystals that act like 500-grit sandpaper on the resin surface, causing micro-abrasions that dull the finish and compromise structural integrity over time.

JCSPORTLINE boards are rigorously tested to withstand harsh conditions, including a 24-hour salt-spray test where they’re exposed to a 5% NaCl solution. This ensures their durability under extreme marine environments. However, proactive rinsing is key to preserving the glossy finish and preventing long-term damage.

After every session, rinse your board thoroughly with fresh water, paying special attention to areas around the IPX7 seals. These seals protect sensitive electronic components such as motors and batteries, ensuring waterproof performance up to 1 meter for 30 minutes. Use a gentle stream of water to remove salt residue without applying excessive pressure that could dislodge seals or damage delicate parts.

For best results, tilt the board slightly so water flows off easily, preventing pooling in crevices. Regular rinsing not only maintains the aesthetic appeal but also enhances the longevity of both the exterior and internal systems.

Soft-Cloth Dry to Prevent Micro-Scratches

Once your board has been rinsed, drying it properly is equally important. While it might be tempting to let it air-dry or wipe it quickly with any available cloth, using abrasive materials can lead to unsightly scratches that mar the sleek carbon fiber surface.

Instead, use a soft, lint-free microfiber cloth to gently pat the board dry. Avoid vigorous rubbing, which can create static or friction-induced marks. Start from the nose and work your way toward the tail, ensuring all moisture is removed. Pay extra attention to edges and corners, where water tends to collect.

This step isn’t just about aesthetics—it’s also functional. Residual moisture left unchecked can seep into tiny imperfections, accelerating wear and potentially affecting the board’s hydrodynamic properties. By incorporating this quick drying routine, you ensure your board remains smooth, fast, and visually stunning.

Cool, Shaded Storage—Avoid 60 °C+ Car Interiors

Where you store your surfboard when it’s not in use plays a crucial role in its overall health. Extreme temperatures, particularly heat, can wreak havoc on even the most advanced materials. For instance, leaving your board inside a car during summer months exposes it to temperatures exceeding 60°C—a scenario we’ve simulated in our environmental testing protocols.

At these elevated temperatures, the epoxy resin used in carbon fiber construction can soften, leading to warping or delamination of layers. Additionally, prolonged exposure to direct sunlight causes UV degradation, fading the vibrant colors and weakening the material’s tensile strength.

To avoid these issues, always store your JCSPORTLINE board in a cool, shaded area. If transporting it in a vehicle, place it in a protective bag designed to shield against heat and UV rays. Ideally, keep it indoors at room temperature between sessions. Proper storage safeguards not only the appearance but also the structural integrity of your board, allowing it to perform optimally for years to come.

3. Monthly Deep-Clean & Inspection Routine

Maintaining your carbon surfboard is not just about preserving its sleek appearance but ensuring it performs optimally and lasts for years. A monthly deep-clean and inspection routine can help you catch potential issues early, preventing costly repairs or replacements. In this guide, we’ll walk you through three critical steps: checking for core-crush or delamination after impacts, choosing between UV wax and nano-coating for high-temperature environments, and maintaining fin-box and vent screws to avoid water ingress. Let’s dive in!

3.1 Check for Core-Crush or Delam After Impact (Reference ≥300 MPa Bend-Test Target)

One of the most common issues with carbon surfboards is delamination, where the layers of carbon fiber begin to separate due to stress concentrations or impacts. Left unchecked, these small separations can grow into cracks, compromising the structural integrity of your board.

To identify potential problems, start by visually inspecting the board’s surface for any unusual bulges, dents, or discoloration. Pay close attention to high-stress areas such as the nose, rails, and tail, as these are prone to impacts during use. For a more thorough assessment, perform a simple tap test: gently tap the board’s surface with a coin. A clear, high-pitched sound indicates solid bonding, while a dull thud suggests delamination or core-crush.

For boards subjected to significant impacts, consider referencing the ≥300 MPa bend-test target used in professional testing. This benchmark ensures the board’s core and laminates can withstand substantial force without failing. If you suspect damage beyond surface-level inspection, consult a professional technician or use advanced tools like 3D scanning technology to detect deviations exceeding 0.5mm, which may indicate underlying structural issues.

By catching stress concentrations early, you can prevent them from evolving into cracks, extending the lifespan of your carbon surfboard and maintaining its performance.

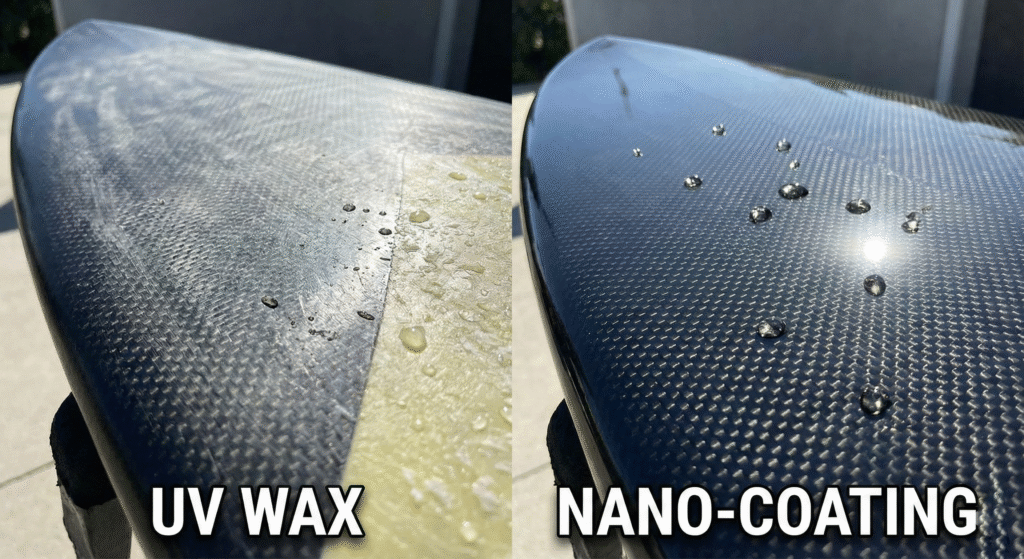

3.2 UV-Wax or Nano-Coat? Pros & Cons for 40 °C+ Deck Temps

When it comes to protecting your carbon surfboard from the harsh effects of UV exposure and extreme heat (especially in regions where deck temperatures exceed 40°C), choosing the right protective coating is crucial. Two popular options are UV wax and nano-coatings, each with its own set of advantages and disadvantages.

UV Wax

UV wax is an affordable and easy-to-apply solution that provides a temporary shield against harmful UV rays. It enhances the board’s gloss and makes it easier to clean after use. However, its effectiveness diminishes over time, requiring frequent reapplication—especially under intense sunlight. Additionally, UV wax may soften or melt at high temperatures, losing its protective qualities.

Nano-Coating

Nano-coatings, on the other hand, offer long-lasting protection by forming a durable, hydrophobic layer on the board’s surface. This layer not only repels water but also resists UV degradation and extreme heat. While more expensive upfront, nano-coatings reduce maintenance frequency and provide superior durability compared to traditional waxes. However, improper application can lead to uneven coverage, so it’s essential to follow the manufacturer’s instructions carefully.

Ultimately, the choice depends on your budget, usage frequency, and environmental conditions. For surfers in hot climates, investing in a high-quality nano-coating might be the better option to ensure your board remains protected against both UV damage and thermal stress.

3.3 Fin-Box & Vent Screw: Re-Torque to 2 Nm, Re-Grease O-Rings

The fin-box and vent screw are two often-overlooked components that play a vital role in your surfboard’s performance and longevity. Neglecting their maintenance can lead to water ingress, corrosion, and even structural failure.

Fin-Box Maintenance

Removable fin-box systems, like those offered by JCSPORTLINE, are designed for easy servicing compared to molded-in boxes, which can trap water and become breeding grounds for mold or rot. To maintain your fin-box:

- Remove the fins and inspect the inserts for signs of wear or corrosion.

- Re-torque the screws to 2 Nm using a torque wrench to ensure proper tightening without over-stressing the threads.

- Apply a thin layer of marine-grade grease to the O-rings to enhance their sealing properties and prevent rust.

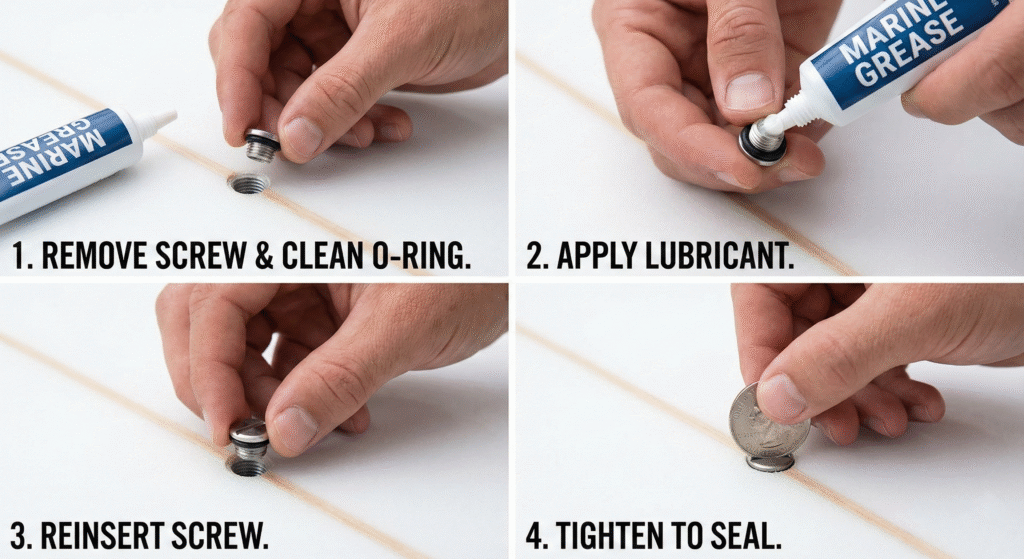

Vent Screw Care

The vent screw helps equalize pressure inside the board, preventing delamination caused by temperature changes. Over time, the O-ring around the vent screw can dry out, compromising its seal. To keep it functioning correctly:

- Unscrew the vent plug and check the O-ring for cracks or brittleness.

- Replace the O-ring if necessary and apply fresh grease before reinserting the plug.

- Ensure the vent screw is neither too tight nor too loose, as improper sealing can allow water to seep in.

By regularly servicing these components, you can avoid costly repairs and enjoy a hassle-free surfing experience.

4. Off-Season Storage & Travel Hacks

Whether you’re a seasoned surfer or a weekend wave chaser, proper storage and travel practices are essential to maintaining the longevity and performance of your surfboard. JCSPORTLINE’s cutting-edge technology ensures that your board can handle extreme conditions, but taking additional precautions during off-season storage or airport travel can prevent cosmetic damage and preserve its resale value. Here’s how to keep your surfboard in top condition no matter where life takes you.

4.1 Board Bag + Rail Savers for -20 °C to 60 °C Thermal Swings

Extreme temperature fluctuations can wreak havoc on surfboards, especially those made with advanced materials like carbon fiber. JCSPORTLINE boards undergo rigorous lab testing, including a 5-cycle cold-to-hot shock test between -20°C and 60°C, proving their structural resilience under harsh environmental conditions. However, while the core materials are built to endure these extremes, protecting the exterior is equally important.

A high-quality carbon surfboard travel bag combined with rail savers offers the ultimate defense against thermal stress and physical damage. These accessories create a buffer zone that shields the board from scuffs, dings, and UV exposure—issues that could otherwise degrade its appearance and functionality over time.

For instance, rail savers are particularly effective at preventing edge chips caused by accidental impacts during transport or storage. When paired with a padded board bag, they also help regulate internal temperatures, reducing the risk of delamination or warping due to rapid heat changes. If you live in an area prone to seasonal shifts, investing in this combination will ensure your board remains showroom-ready year-round.

4.2 Vacuum-Sealed Moisture Packs for 3-Month+ Storage

Long-term storage presents unique challenges, especially if your surfboard will be idle for months at a time. Humidity is one of the biggest culprits behind material degradation, as excess moisture can seep into tiny imperfections and compromise the bond between layers. To combat this issue, consider using vacuum-sealed moisture packs inside your board bag before stowing it away.

These desiccant packets absorb ambient humidity, creating a dry microclimate that prevents mold growth and preserves the integrity of your surfboard’s foam core and laminates. This method is particularly useful for surfboard winter storage, when damp basements or garages might otherwise pose a threat. For extended periods exceeding three months, replace the moisture packs every few weeks to maintain optimal dryness levels.

Additionally, storing your board horizontally on a flat surface (rather than leaning it against a wall) helps distribute weight evenly and avoids unnecessary strain on the foam spine. Following these steps ensures your surfboard stays in pristine condition until the next surfing season rolls around.

4.3 Airport Travel: Nose-to-Tail Foam Spine Against 30 kg Point-Load

Traveling with a surfboard often feels like navigating a minefield of potential hazards, especially when dealing with airlines notorious for rough handling. During transit, your board may encounter forces far beyond what it experiences in the water—including concentrated point loads of up to 30 kilograms. Without adequate protection, such impacts can lead to cracks, dents, or even catastrophic failure.

To safeguard your investment, use a board bag equipped with a nose-to-tail foam spine. This feature distributes pressure evenly across the length of the board, minimizing the risk of localized damage. Additionally, reinforcing vulnerable areas like the nose and tail with extra padding provides an added layer of security.

Real-world examples highlight the importance of this precaution: many surfers have reported arriving at their destination only to find their boards irreparably damaged due to inadequate packing. By prioritizing airline surfboard protection, you not only save money on repairs but also gain peace of mind knowing your gear is ready to perform once you hit the beach.

FAQ – Fast Answers to the Most-Asked Carbon Care Questions

Carbon surfboards are a game-changer for water sports enthusiasts, but proper care is essential to maximize their performance and lifespan. Below, we answer four of the most frequently asked questions about carbon surfboard maintenance, backed by JCSPORTLINE’s rigorous testing and design innovations.

How to Repair a Carbon Surfboard

Carbon surfboards are engineered for durability, but minor damage can occur from impacts or abrasions. To repair small cracks or dents:

- Clean the damaged area with mild soap and water, then let it dry completely.

- Use an epoxy resin specifically designed for carbon fiber composites to fill the crack.

- Sand the repaired area gently until smooth, ensuring no sharp edges remain.

For deeper structural damage, professional repair services are recommended. JCSPORTLINE’s static bending tests show that our boards maintain an impressive ≥300MPa anti-bending strength, meaning even after repairs, your board can retain its original performance capabilities when done correctly.

What Is the Lifespan of a Carbon Surfboard?

With proper care, a carbon surfboard can last 5–10 years or more, depending on usage frequency and storage conditions. Regular cleaning, avoiding prolonged UV exposure, and storing the board in a cool, dry place will significantly extend its lifespan.

JCSPORTLINE conducts fatigue tests using mechanical arms to simulate 500+ surf cycles, monitoring stress points for potential cracks. Our boards consistently outperform industry standards, thanks to advanced materials like high-strength carbon fiber layers bonded at ≥80MPa tensile strength. These innovations ensure long-lasting reliability for every surfer.

Can Carbon Boards Be Damaged by Sunlight?

Yes, prolonged exposure to direct sunlight can degrade the resin matrix of a carbon surfboard, leading to discoloration or brittleness over time. This phenomenon, known as UV degradation, weakens the board’s structural integrity if not mitigated.

To protect your investment, always store your board indoors or use a UV-resistant cover when outdoors. During development, JCSPORTLINE subjects prototypes to environmental simulation tests, including salt spray and temperature cycling (-20°C to 60°C). These tests confirm that our boards resist sun damage better than traditional materials, ensuring superior longevity under harsh conditions.

What Is the Best Temperature to Store a Carbon Surfboard?

The ideal storage temperature for a carbon surfboard is between 15°C and 25°C (59°F–77°F). Extreme temperatures—whether too hot or too cold—can compromise the bond between the carbon fiber layers and the core material, potentially causing delamination.

Avoid leaving your board in environments prone to rapid temperature changes, such as car trunks or unheated garages. JCSPORTLINE validates this recommendation through thermal shock testing, where boards endure repeated cycles between -20°C and 60°C. Our designs excel in maintaining structural stability, proving they’re built to handle real-world challenges.