Table of Contents

Introduction to Carbon Fiber

- Carbon fiber has been used for 20-30 years in high performance applications like aerospace, Formula 1, and sporting goods. In the early days, carbon fiber originated as a premium material with limited use in niche applications due to high costs and specialized characteristics.

- The use of carbon fiber composites reduces fuel consumption and emissions by enabling lightweight vehicles, planes, and wind turbines.

- Carbon fiber is produced less efficiently than glass fiber, with ~50% yield from PAN precursor and slower, energy-intensive manufacturing processes.

- Recent years show increased demand for industrial-grade fibers and thermoplastic resin systems, expanding applications in automotive applications and green energy.

- Carbon fiber materials offer high strength, light weight, and resistance to harsh environments, making them ideal for various industries. Compared to metal components, carbon fiber provides significant weight reduction benefits.

Industry Background

Market Trends

- The automotive sector drives significant carbon fiber demand due to lightweighting, reducing component weight and improving fuel efficiency and emissions. Other sectors, such as aerospace and sports equipment, also contribute to increased demand.

- Carbon fiber composites are used in electronics for durable, lightweight components like laptop housings and connectors.

- Wind energy also drives carbon fiber demand, with applications ranging from longer, stronger turbine blades to lightweight, high performance composites used in various components.

- The market demands high-performance materials, innovative solutions, and customized products, which carbon fiber can provide.

- Industry trends include vertical integration, growth in thermoplastic composites, and global supply chain agility to meet expanding market demands.

Manufacturing and Quality

- Carbon fiber is manufactured through a complex process that involves significant technological challenges, high energy consumption, and specialized equipment. This makes the manufacture of high-performance fibers both costly and demanding compared to other materials.

Manufacturing Process

- The manufacturing process of carbon fiber involves high-temperature and high-pressure treatments to produce high-modulus fibers, with the final product being produced from raw materials such as polyacrylonitrile (PAN).

- Quality control is crucial in carbon fiber production to ensure consistent performance characteristics and meet market demands.

- Proprietary technology and advanced capabilities enable precision-engineered, cost-efficient, and agile production tailored to customer needs.

- The production process involves various stages, including fiber production, composite manufacturing, and finishing, which are combined to optimize performance and efficiency.

- High-performance solutions require careful selection of materials, manufacturing processes, and quality control measures.

Materials and Properties

Composite Materials

- Carbon fiber composite materials offer a broad range of properties, including high strength, low weight, and resistance to corrosion.

- Composite materials can be tailored to meet specific performance requirements, such as tensile strength, high temperatures, and unique demands.

- The choice of materials, including fibers, resins, and fillers, affects the final properties of the composite.

- Carbon fiber composites can be used in various applications, including automotive, aerospace, and industrial sectors.

- The properties of carbon fiber composites make them an attractive alternative to traditional materials like aluminum and steel.

Carbon Fiber Parts and Applications

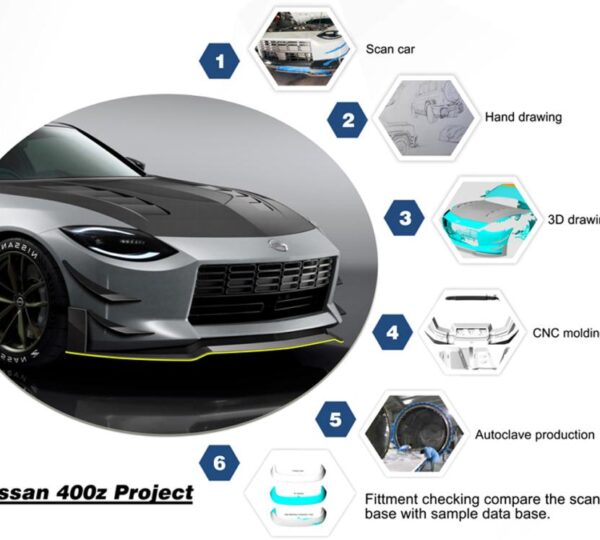

- We manufacture custom carbon fiber parts for a wide range of industries, including automotive applications, where lightweight, high-performance, and durable components are essential for vehicle efficiency and safety.

- Our team collaborates with clients on diverse projects, offering customized solutions tailored to specific engineering requirements and challenging applications.

- Whether you need a single prototype or large quantity production, we have the expertise and innovation to develop parts that meet your vision and sector needs.

Customization Options

- Custom carbon fiber parts can be designed and manufactured as customized solutions to meet specific customer requirements.

- Carbon fiber products can be tailored to provide high performance, durability, and resistance to harsh environments.

- The use of carbon fiber composites enables the production of complex shapes and structures with high precision and accuracy.

- Carbon fiber parts can be used in various applications, including automotive, aerospace, and industrial sectors.

- Customization options include varying fiber orientations, resin systems, and manufacturing processes to achieve specific performance characteristics and to realize the client’s vision.

Innovative Solutions

- Innovative solutions in carbon fiber customization involve the use of proprietary technologies, advanced materials, and manufacturing processes, with a strong focus on innovation to deliver unique and competitive products.

- Recent innovations in carbon fiber materials and production methods have led to significant advancements in performance, recyclability, and application-specific properties.

- Engineering teams work to develop new carbon fiber composite materials, enabling the creation of high-performance products tailored to specific needs.

- Carbon fiber composites can be used to produce complex structures and shapes with high precision and accuracy.

- The use of carbon fiber enables the production of lightweight, high-strength components with improved performance characteristics.

- Innovative solutions in carbon fiber customization require collaboration between manufacturers, engineers, and customers to meet specific requirements.

Machining and Finishing

- Machining and finishing of carbon fiber parts require specialized equipment and techniques to achieve high precision and accuracy.

- The use of advanced machining technologies, such as CNC machines, enables the production of complex shapes and structures.

- Finishing processes, such as polishing and coating, can enhance the appearance and performance of carbon fiber parts.

- Machining and finishing operations must be carefully controlled to avoid damage to the carbon fiber material.

- The choice of machining and finishing processes affects the final properties and appearance of the carbon fiber part.

Adhesives and Assembly

- Adhesives play a critical role in the assembly of carbon fiber parts, enabling the creation of strong and durable bonds.

- The choice of adhesive depends on the specific application, performance requirements, and environmental conditions.

- Assembly processes, such as bonding and fastening, must be carefully controlled to ensure high-quality and reliable joints.

- The use of advanced adhesives and assembly techniques enables the production of complex structures and shapes with high precision and accuracy.

- Adhesives and assembly processes must be compatible with the carbon fiber material and other components to ensure optimal performance.

Sustainability and Environmental Impact

- The production of carbon fiber has a significant environmental impact, including energy consumption and waste generation.

- Sustainable manufacturing processes and materials can reduce the environmental footprint of carbon fiber production.

- The use of recycled carbon fiber and end-of-life recycling can minimize waste and reduce the demand for virgin materials.

- Carbon fiber composites can enable the production of more fuel-efficient vehicles, reducing greenhouse gas emissions and environmental impact.

- The development of sustainable carbon fiber production methods and materials is essential for reducing the environmental impact of the industry.

- Industry organizations play a key role in promoting sustainable practices across the carbon fiber sector by facilitating collaboration, knowledge sharing, and the adoption of best practices.

Customer Experience

Streamlined Ordering Process

- A streamlined ordering process enables customers to easily specify their requirements and receive high-quality carbon fiber parts.

- Effective communication and collaboration between customers and manufacturers are crucial for ensuring that requirements are met.

- The use of advanced technologies, such as online platforms and CAD software, can facilitate the ordering process and improve efficiency.

- A customer-centric approach ensures that products meet specific requirements and provide high performance and value.

- The ordering process should be flexible and adaptable to accommodate changing customer needs and requirements.

Expertise and Support

- Expertise and capabilities in carbon fiber customization require a deep understanding of materials, manufacturing processes, and applications.

- Manufacturers must provide engineering technical support and guidance to customers to ensure that products meet specific requirements.

- A focus on collaboration between manufacturers, engineers, and customers is essential for developing innovative solutions and high-performance products.

- The development of new carbon fiber composite materials and production methods requires ongoing research and development.

- Manufacturers must stay up-to-date with the latest technologies and trends to remain a leading provider of high-quality products and services.

Certification and Compliance

- Certification and compliance are essential in carbon fiber customization, as they ensure that products meet specific industry standards and regulations.

- The use of certified materials and manufacturing processes enables the creation of high-quality products.

- Compliance with industry standards and regulations requires ongoing testing and inspection.

- Certification and compliance must be carefully controlled to ensure that products meet specific customer requirements and industry trends.

- The development of new carbon fiber composite materials and production methods requires certification and compliance with industry standards and regulations.

Play