Table of Contents

Have you ever wondered why producing one custom carbon fiber part might take just 15 days, but a batch of 20 pieces can take 30 days?

The answer lies in the manufacturing process, mold efficiency, and strict quality control that ensure every part meets high standards.

1. Understanding the Carbon Fiber Manufacturing Process

Producing high-quality carbon fiber parts is not just about shaping material—it’s a multi-step process that requires precision and time.

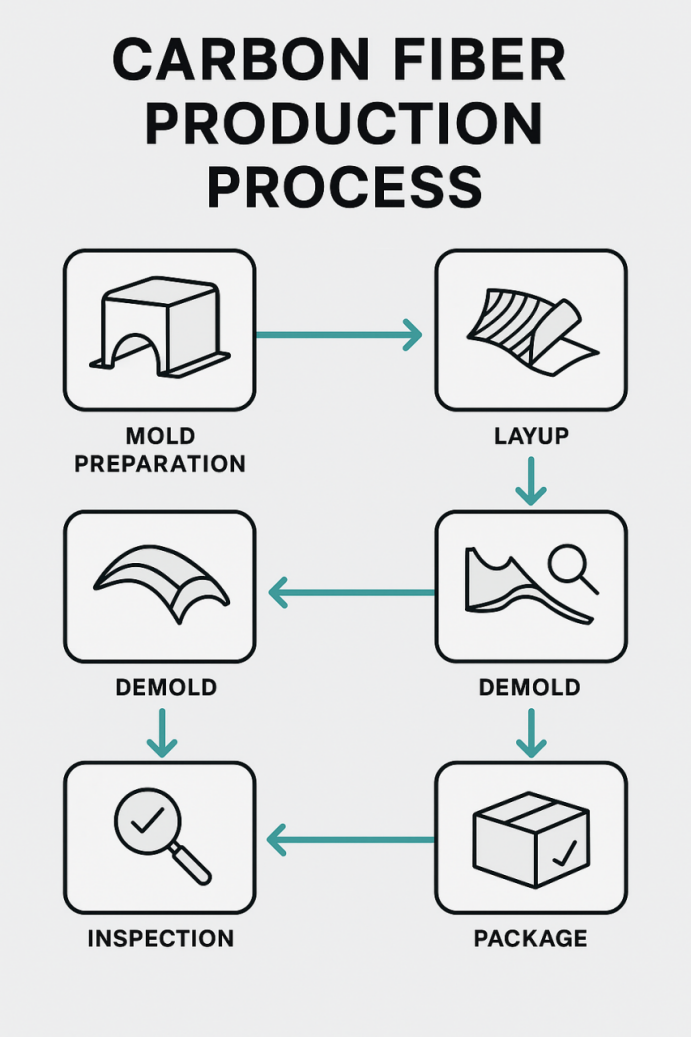

Here’s a simplified breakdown of the steps:

- Mold preparation – The mold is cleaned, polished, and treated to ensure a smooth release.

- Layering and resin application – Carbon fiber sheets are cut, placed into the mold, and impregnated with resin.

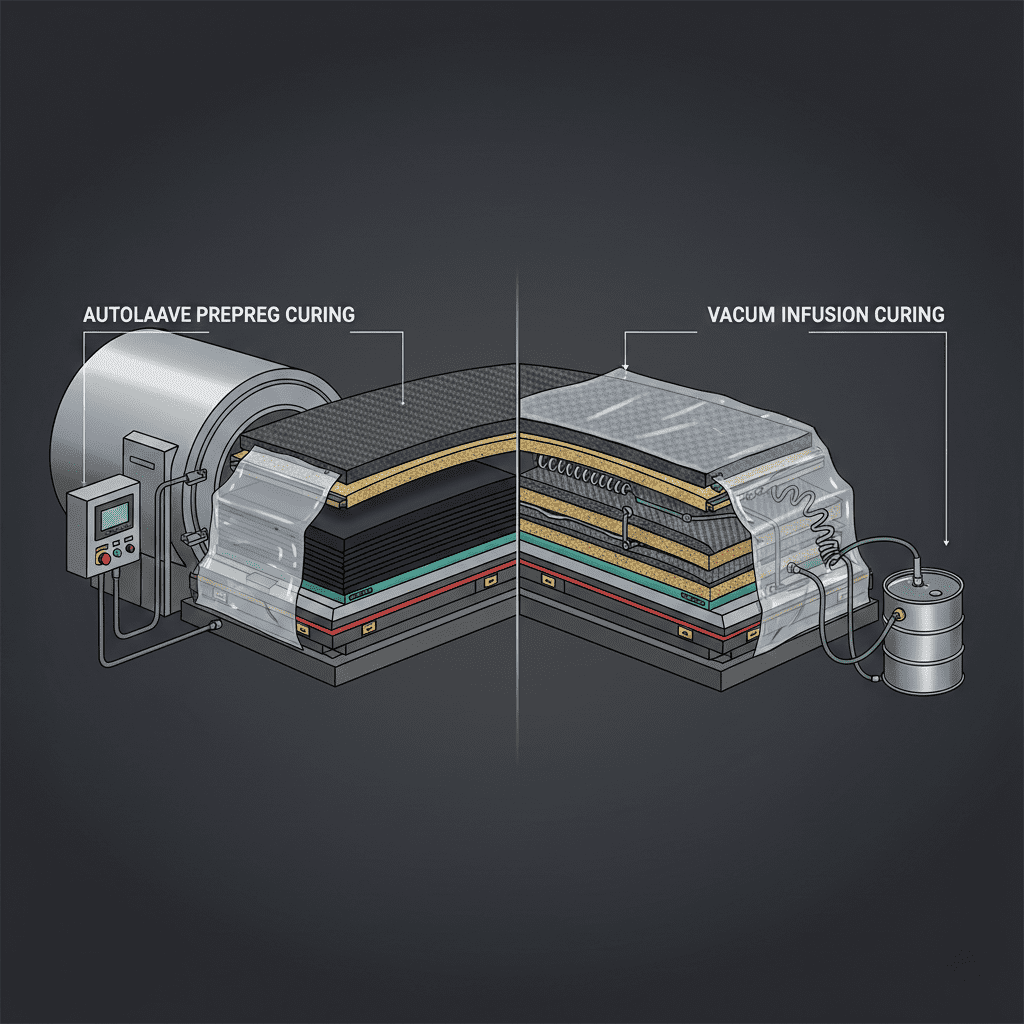

- Vacuum bagging or autoclave curing – This step removes air bubbles and strengthens the part.

- Cooling and demolding – The part is removed and checked for defects.

- Trimming, sanding, and finishing – Surfaces are refined for a perfect fit and look.

- Final inspection – Every part undergoes a strict quality check before packing.

- Key takeaway: Each step has a fixed time requirement that doesn’t scale perfectly when producing more parts.

2. Mold Efficiency – The Real Bottleneck

Simple molds for small parts can be reused quickly, but complex molds—such as those for large body panels—require:

- Longer curing times

- Careful cleaning between cycles

- Precision re-coating for every use

For 20 units, the same mold might be used multiple times, which slows down production because the mold can only handle one curing cycle at a time.

3. Quality Control – Why It Adds Time, Not Just Value

Strict quality assurance (QA) is essential for automotive-grade carbon fiber components:

- Every piece is checked for cracks, air bubbles, or uneven resin.

- Defective parts are reworked or remade, which extends production time.

- This process ensures the final product meets international standards for strength, weight, and appearance.

4. Why Batches Take Longer Than Single Orders

When producing a single carbon fiber part, the manufacturing flow is straightforward—one mold cycle, one quality check.

But in batch production:

- The mold must be cycled multiple times.

- QA is done for each part individually.

- Logistics and packing take longer.

That’s why 20 units can take nearly double the lead time of a single order.

5. How This Affects Your Business Planning

For distributors, auto tuners, and custom car builders, understanding carbon fiber production lead times is essential for:

- Accurate order scheduling

- Inventory management

- Avoiding delays in client deliveries

By knowing the production process, you can better plan your supply chain and stock levels.

6. Get a Custom Production Plan

At JCSPORTLINE, we can tailor production schedules to meet your needs:

- Custom lead times for urgent orders

- Flexible mold allocation for large projects

- Transparent production updates for better planning

📞 Contact us today to discuss your project.

🌐 Visit our website to explore our full range of carbon fiber parts for BMW, Porsche, and other performance vehicles.

📩 Subscribe to get updates on new products, manufacturing improvements, and industry trends.