Table of Contents

The 4 Critical Decision Gates Every Project Must Pass

Most carbon fiber project failures are not caused by manufacturing issues.

They are the result of design decisions made too late.

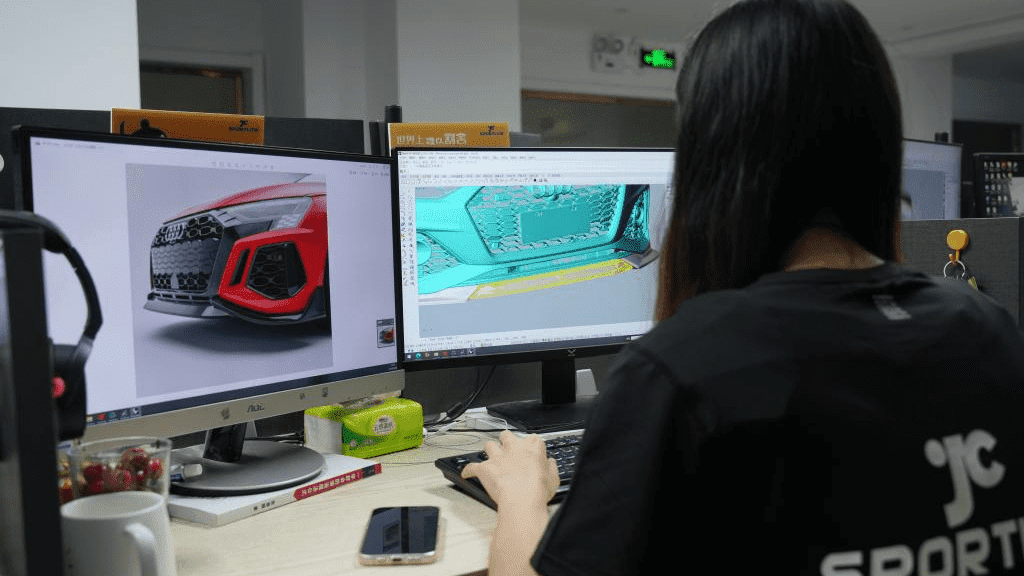

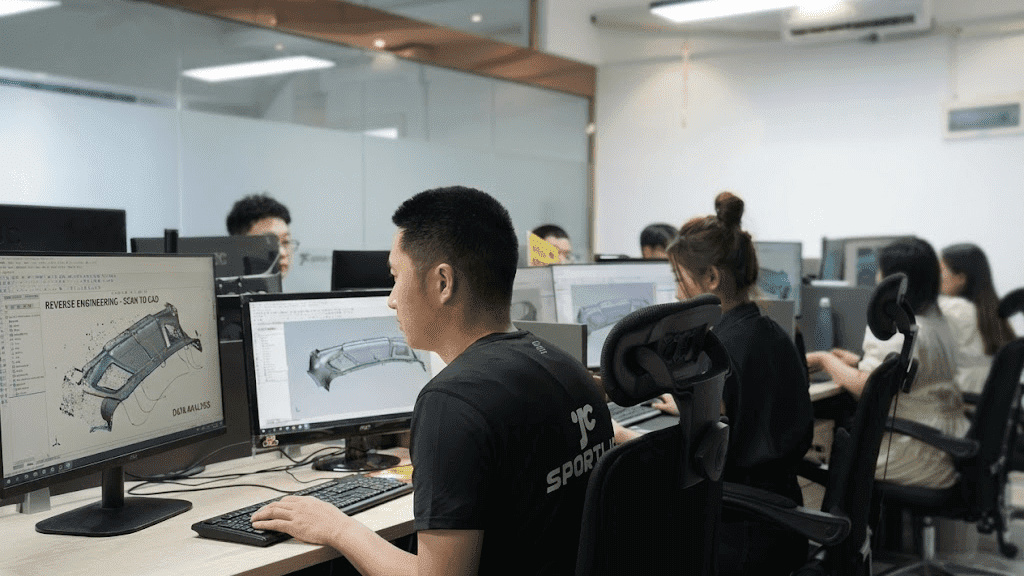

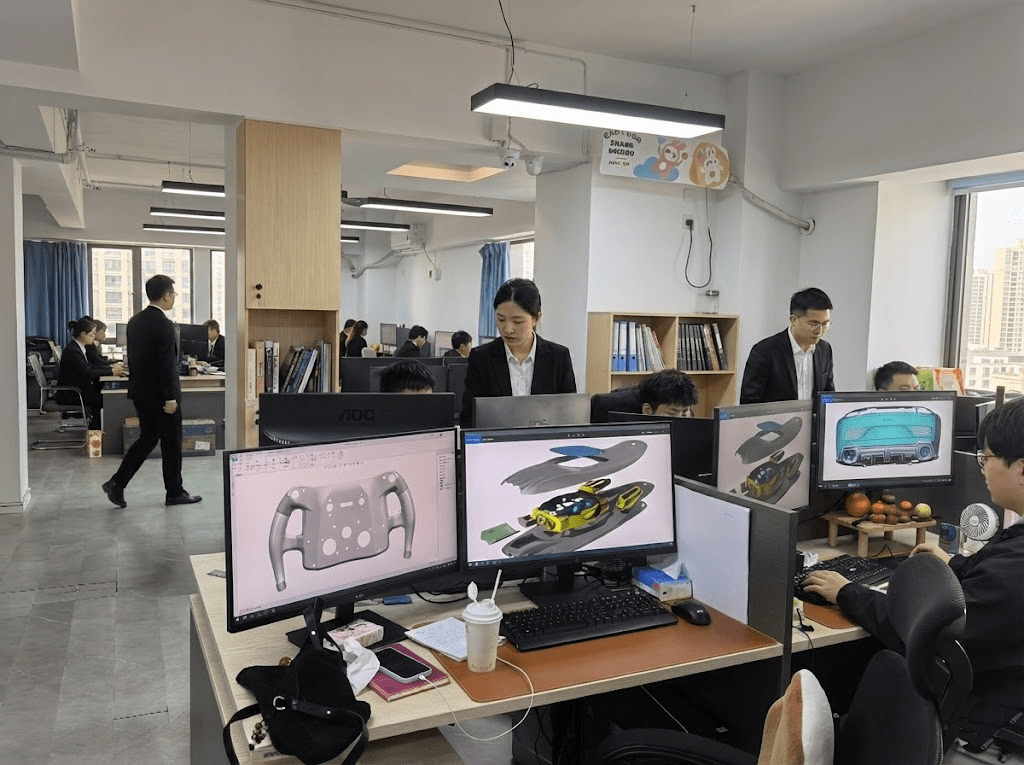

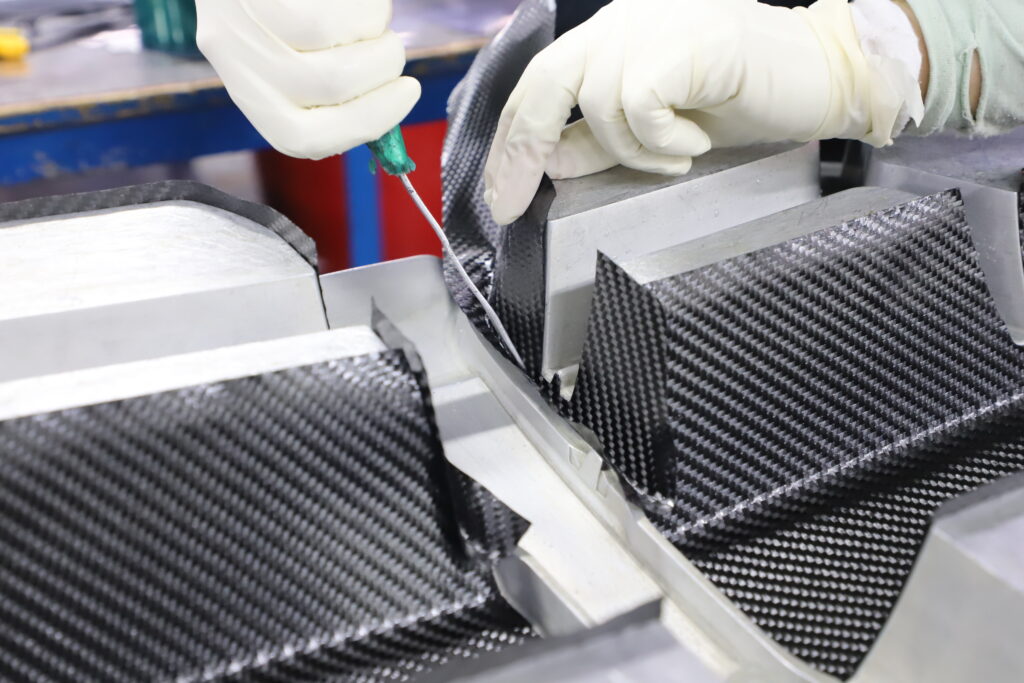

At JCSPORTLINE, carbon fiber design is treated as an engineering-driven decision process, not a styling exercise. Long before tooling is built or production begins, every project must pass four critical design gates that determine whether a concept can become a reliable, production-ready composite part.

These gates form the foundation of our Carbon Fiber Design Services, ensuring that design intent, engineering feasibility, and manufacturing reality are aligned from the very beginning.

Gate 1: Design for Manufacturability Starts in CAD

DFM Scorecard — Geometry, Draft, and Fiber Logic

The moment a CAD file is received, the most important work begins.

Within 24 hours, our engineers apply a 12-point Design for Manufacturability (DFM) scorecard to evaluate whether the design can realistically move beyond concept.

Key design checks include:

- Wall Thickness

Structural carbon fiber parts require a minimum wall thickness of 1.5 mm (0.06 in) to ensure consistent consolidation and mechanical integrity. - Draft Angles

Vertical surfaces must maintain at least 1.5° draft to allow proper demolding. Designs without sufficient draft often fail during vacuum bagging or tool release. - Fiber Orientation Strategy

A quasi-isotropic 0/45/-45/90° layup is commonly applied during early design to balance stiffness and strength across load directions. - Ply Termination Radius

Ply drop-offs require a minimum 0.8 mm radius to prevent stress concentration and premature fatigue failure.

Designs that ignore these fundamentals often suffer scrap rates exceeding 30% in volume production. Once tooling is finalized, these issues are expensive—or impossible—to correct.

This is why manufacturability must be addressed at the design stage, not during production.

This early evaluation is a core part of our Engineering & DFM services, allowing design risks to be identified before tooling decisions are locked in.

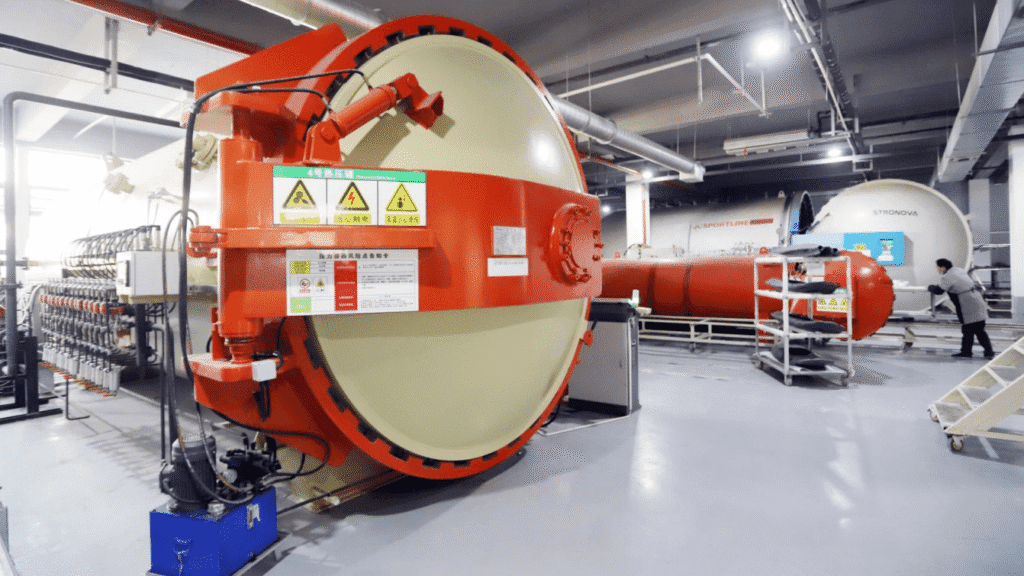

Gate 2: Tooling Strategy Is a Design Decision, Not a Purchasing One

Rapid Tooling vs. Production Tooling

Tooling is frequently treated as a downstream cost problem. In reality, tooling strategy should be defined during design, based on geometry, volume expectations, and validation needs.

| Tool Type | Typical Use | Relative Cost | Design Flexibility |

|---|---|---|---|

| Rapid Tooling | Design validation & early prototypes | Low | High |

| Production Tooling | Stable, high-volume production | High | Limited |

For limited-run or performance-focused programs, JCSPORTLINE often applies hybrid aluminum–nickel tooling, allowing:

- Faster design iteration

- Lower upfront investment

- Reliable performance across 200+ autoclave cycles

In projects under 500 units, this approach can reduce tooling expenditure by over 30% without compromising surface quality or dimensional accuracy.

The key point: tooling efficiency is designed into the part, not negotiated after the design is frozen.

Tooling efficiency is addressed during design through our integrated design-to-production workflow, rather than treated as a downstream manufacturing issue.

Gate 3: Validation Confirms Design Assumptions

Climate, UV, and Environmental Aging

A production-ready design must survive real-world conditions—not just simulations.

To validate surface durability and structural stability, we subject design samples to 2,000-hour Xenon arc aging tests, simulating years of UV exposure, humidity, and thermal cycling.

Typical results include:

- Gloss retention above 92%

- Interlaminar strength loss below 5%

- Color shift (ΔE) under 1.5, meeting premium exterior standards

These results are achieved through design-stage material selection, including resin systems with embedded nanoparticle UV inhibitors.

Validation is not about proving the part works once.

It is about confirming that the design assumptions remain valid over time.

Validation results from this stage are commonly reviewed during our Prototype Development process to confirm design assumptions under real-world conditions.

Gate 4: Cost and Performance Must Be Balanced by Design

Designing for Strength Without Overengineering

Cost optimization in carbon fiber projects does not come from reducing quality—it comes from design intelligence.

Effective strategies include:

- Selective Ply Reinforcement

Reinforcing only high-stress regions rather than increasing global thickness. - Hybrid Material Usage

Incorporating recycled or secondary fibers in non-critical zones without affecting performance. - Optimized Cure Strategy

Combining RTM and autoclave processes to reduce cycle time while maintaining ISO 527 tensile requirements.

| Material System | Weight | Relative Cost | Performance Impact |

|---|---|---|---|

| Fiberglass | Baseline | Low | Limited stiffness |

| JCSPORTLINE Carbon Fiber | −40% | +10–12% | Significant strength & efficiency gains |

Cost-performance tradeoffs like these are evaluated early to prevent redesign during later manufacturing support stages.

The result is a design that meets performance targets without unnecessary cost escalation.

Why These Gates Matter in Carbon Fiber Design Services

Each of these gates represents a decision point that must be resolved during design, not postponed until production.

By addressing manufacturability, tooling strategy, validation, and cost-performance balance early, we help clients:

- Reduce redesign cycles

- Shorten development timelines

- Avoid costly tooling revisions

- Enter production with confidence

This is the philosophy behind JCSPORTLINE’s Carbon Fiber Design Services—where design is treated as a strategic engineering function, not just a visual concept.

These design principles have been applied across real-world projects, including complex automotive exterior and structural components.

Frequently Asked Questions

How long does it take to reach a production-ready design?

Design validation and prototype-ready data are typically completed within 14 days, depending on complexity.

Can tooling strategy be defined before production volume is fixed?

Yes. Early tooling decisions are part of the design process and can adapt as volume expectations evolve.

Do you support PPAP documentation?

Yes. PPAP Level 3 documentation can be prepared within 48 hours, including full traceability.

Ready to Move from Concept to a Production-Ready Design?

Start Your Design Project

Tell us about your concept, performance targets, and production goals.

Our team will help you define the right design path—before costly decisions are locked in.