Table of Contents

Materials & Structure: Why Your Hydrofoil Board Has a Seam

Understanding the Source of Seams

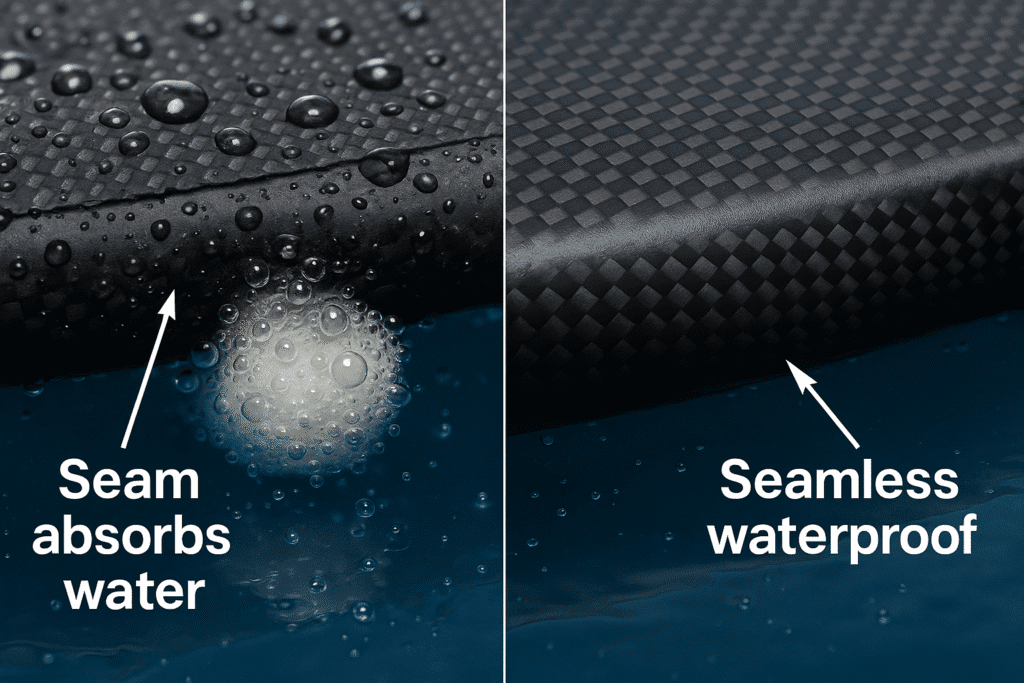

A seam on your hydrofoil board is a visible joint created when two separate mold halves are bonded together. In traditional hand-layup or split-mold construction, carbon fiber layers are applied to each half independently. When cured and joined, the fiber flow breaks at the connection line, leaving a raised or shadowed seam. This joint not only affects aesthetics but also becomes a mechanical weak spot where stress and vibration concentrate over time.

Inside the Structure: Foam Core and Carbon Layers

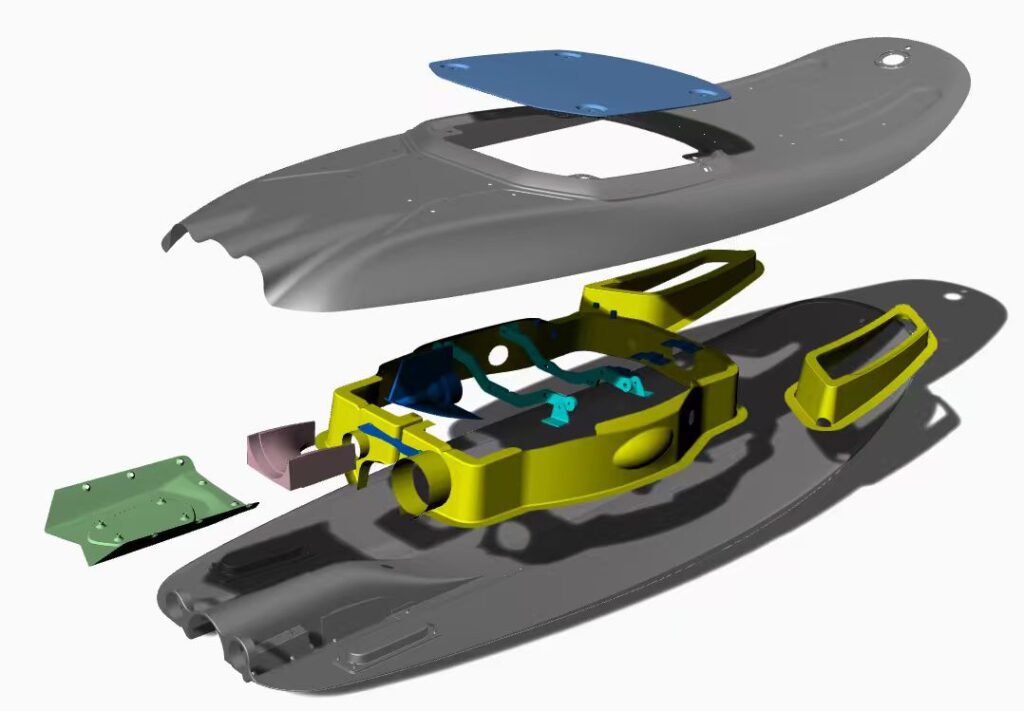

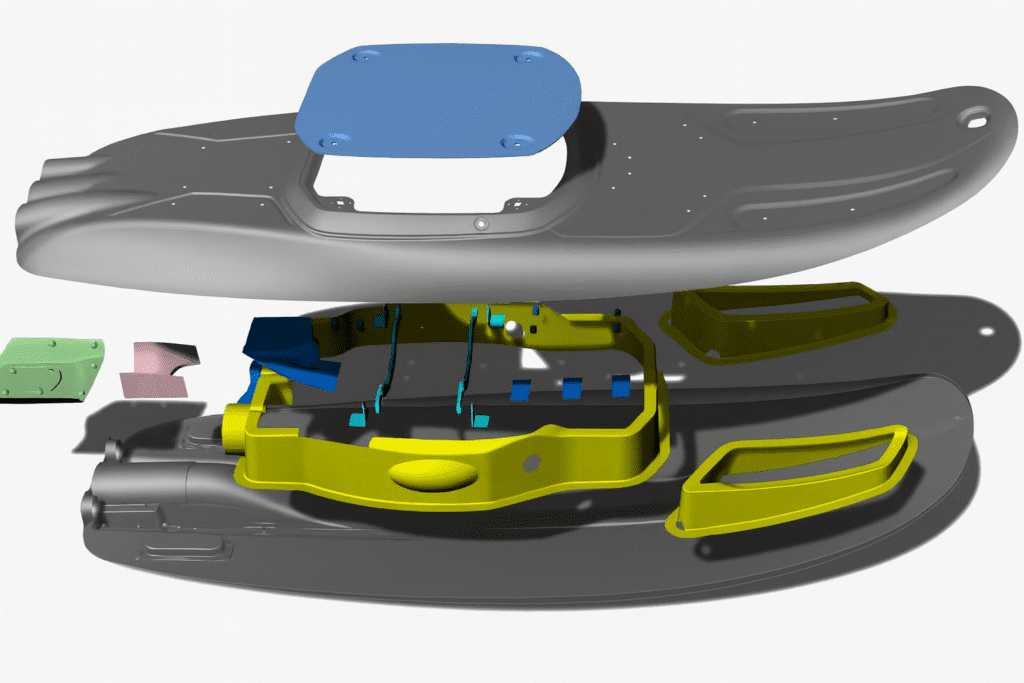

A typical hydrofoil board contains three key elements — the carbon fiber outer shell, a foam core, and internal reinforcement zones around the battery compartment or inserts. In multi-part molds, aligning these elements precisely is difficult. Uneven resin distribution often causes thickness variation or trapped air near the seam area. In contrast, a one-piece carbon shell integrates all layers and cores under vacuum pressure, maintaining uniform density and continuous fiber orientation.

Benefits of One-Piece Carbon Construction

One-piece molding removes the physical joint line entirely. Continuous carbon fibers flow around the board’s contours, improving torsional stiffness and impact resistance. The result is a lighter, cleaner, and more hydrodynamic product. Boards made this way maintain consistent wall thickness and superior sealing — ideal for high-performance or rental use where structural longevity matters.

How to Identify Real One-Piece Boards

To distinguish genuine one-piece boards, inspect the rails and bottom for continuous weave direction. If you can trace a clear line or color shift, it’s likely a split mold. Seamless boards appear smooth even under reflected light, showing unbroken carbon fiber patterns from nose to tail.

Manufacturing Process: Split Molding vs One-Piece Compression

Traditional Hand-Layup: Low Cost, Low Precision

The hand-layup process has long been used for surfboards and hydrofoils due to its simplicity and low tooling cost. Technicians manually place carbon fiber sheets and resin over a foam core inside two separate molds — one for the top and one for the bottom. After curing, both halves are bonded together, forming a visible seam line around the perimeter. However, this approach often results in uneven resin flow, trapped air, and variable thickness between boards. It’s suitable for hobby-level production but lacks the repeatability needed for commercial OEM projects.

Compression Molding: The Transitional Stage

Compression molding improves precision by pressing the carbon fiber layers under controlled temperature and pressure. It uses matched molds that close together, producing a smoother surface and tighter fiber compaction. This process enhances strength-to-weight ratio but still involves two separate mold halves. Minor alignment shifts during curing can cause fiber distortion and surface seam shadows, which still require manual sanding or cosmetic repair.

One-Piece Hot-Press Molding: The Precision Solution

The latest generation of one-piece hot-press molding replaces multi-part bonding with a single integrated mold cavity and fixture system. In this setup, all carbon layers, foam cores, and inserts are placed together before the mold is sealed. The board is then cured under uniform pressure and temperature, producing a continuous carbon shell with zero seam. The use of prepreg carbon fiber ensures consistent resin distribution and fiber alignment, leading to superior mechanical properties and surface quality.

Why One-Piece Matters for OEM & ODM Buyers

For OEM buyers, the one-piece process offers quantifiable advantages:

- Tolerance Control: ±0.3 mm across the shell.

- Surface Finish: Seamless gloss or matte carbon without polishing.

- Durability: No bonding line means fewer delamination risks.

- Production Efficiency: Single mold reduces assembly and QC time.

These factors make one-piece compression molding the preferred standard for high-end hydrofoil and surfboard manufacturing.

Performance & Testing: How Seams Affect Strength and Longevity

Why Seams Weaken Structural Integrity

Every seam represents a discontinuity in the carbon fiber layers — a point where fibers stop transferring load smoothly. During flexing, torsion, or wave impact, this discontinuity becomes a stress concentration zone, accelerating micro-cracks and delamination. Split-mold boards often exhibit reduced torsional stiffness and inconsistent rigidity, especially near the bonding line. In repeated use, these weak points may compromise hydrodynamic stability and cause unwanted vibration at high speeds.

Testing the Impact: Bending, Torsion, and Fatigue

Laboratory testing under ASTM D790 bending and torsion fatigue cycles shows that split-mold boards lose structural stiffness up to 8–12% faster than one-piece designs. Water ingress through seams also alters the foam core’s density, increasing overall weight and lowering rebound strength.

By contrast, vacuum-cured one-piece shells maintain a uniform fiber path, allowing forces to flow continuously from nose to tail. The result: higher load-bearing capacity, smoother performance under lift, and prolonged fatigue life in demanding saltwater conditions.

The Role of Vacuum Curing in Carbon Stability

Vacuum curing under controlled temperature and pressure removes trapped air, enabling consistent resin wet-out across the laminate. This eliminates microbubbles — a common failure origin in hand-layup boards. Continuous prepreg carbon layers ensure the ideal fiber-to-resin ratio, optimizing stiffness while keeping weight low. The outcome is a more predictable and repeatable mechanical profile, critical for professional riders and OEM consistency.

Real-World Effects: Why Strength Matters Beyond the Lab

A stiffer, seamless board not only lasts longer but also performs better. Without flexing at seam joints, riders experience cleaner foil lift, better energy transfer, and less vibration feedback. This structural reliability translates into lower maintenance costs and fewer warranty claims for brands and distributors, especially those supplying clubs or rental fleets.

Durability & Maintenance: How Seams Impact Waterproofing

How Temperature and Pressure Create Micro-Cracks

When exposed to repeated cycles of heat and humidity, the bonded joint between two mold halves expands and contracts at different rates. This creates micro-cracks along the seam area—especially where resin buildup is uneven. Over time, these cracks become capillary channels that draw in water under pressure. This is the leading cause of foam-core swelling and surface bubbling found in older split-mold hydrofoil boards.

The Hidden Cost of Water Ingress

Once moisture enters through a seam, it seeps into the foam core and spreads laterally. The trapped water not only increases the board’s overall weight but also weakens the adhesive bond between the inner core and outer carbon shell. In saltwater environments, the problem escalates—salt crystals corrode around metal inserts, causing internal stress and delamination. Eventually, the board feels sluggish, heavy, and unstable, even if the outer finish looks intact.

Why One-Piece Carbon Shells Stay Dry and Stable

A one-piece carbon fiber shell eliminates the primary failure path for moisture. The continuous laminate forms a sealed barrier that expands uniformly with temperature, preventing micro-crack formation. Combined with vacuum curing and proper O-ring sealing around inserts, this approach keeps the board dry, lightweight, and maintenance-free for years. Many professional fleets and rental clubs now prefer one-piece construction to reduce downtime and annual repair costs.

Practical Maintenance Tips for Long-Term Use

Even seamless carbon boards benefit from routine care. Rinse thoroughly with freshwater after each saltwater session, avoid prolonged UV exposure, and check insert areas for scratches or dents. For older boards with minor seams, apply a marine-grade epoxy sealing coat annually to delay degradation. Regular inspection and preventive sealing are key to maximizing durability.

Customization & Production: Achieving Seamless Precision at Scale

CNC-Machined Molds: The Foundation of Accuracy

High-quality carbon fiber molds start with precision machining. JCSportline uses CNC-milled aluminum molds that can withstand heat and maintain shape stability through thousands of curing cycles. Unlike fiberglass or wood molds that deform over time, aluminum tooling guarantees consistent dimensions, surface smoothness, and ±0.3 mm tolerance across all production runs. This precision ensures that every hydrofoil board fits perfectly, with zero misalignment or warping during compression.

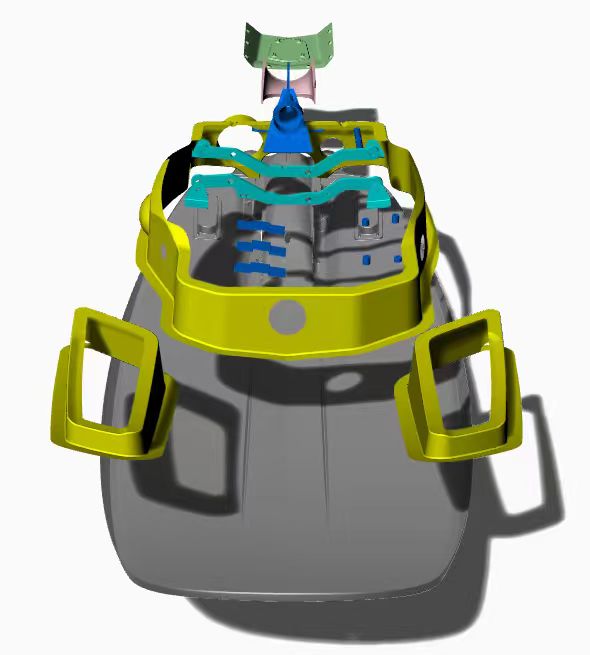

Dedicated Fixtures for Consistency and Seamless Results

During one-piece molding, the mold is paired with custom-built fixtures that secure inserts, battery housings, and core components in place. These fixtures maintain accurate geometry throughout curing, preventing any shift that could cause internal stress or cosmetic seam lines. The process allows for repeatable high-volume production while maintaining the same seamless exterior that defines premium carbon craftsmanship.

Integrating OEM/ODM Customization into the Workflow

Beyond precision, JCSportline supports full OEM and ODM customization. Clients can request adjustments in fiber orientation, surface finish (gloss, matte, or forged), and even embossed or painted logos directly within the CAD model. The team converts digital designs into CNC mold data, minimizing prototype revisions and enabling seamless brand integration. This workflow helps distributors and brands shorten go-to-market timelines without compromising quality.

Scaling Up: From Prototype to Mass Production

Once the mold and fixtures are finalized, the production process transitions smoothly from sample to mass manufacturing. The same digital parameters used for prototyping guide large-batch operations—ensuring identical shape, resin content, and fiber layout across hundreds of units. For international clients, this scalability guarantees reliable delivery schedules and uniform performance, key to sustaining brand reputation in competitive water-sports markets.

Case Studies & Delivery: Why Premium Brands Choose One-Piece Design

Industry Shift: From Hand Layup to Precision Molding

Over the past decade, the hydrofoil and surfboard industry has undergone a manufacturing transformation. Traditional hand-layup factories—especially in Thailand and Europe—once dominated the market due to low tooling costs. However, their limitations in precision, consistency, and waterproofing have pushed premium brands toward one-piece compression and autoclave molding. The demand for seamless, high-strength structures has made Asia’s composite factories the new global standard for performance boards.

JCSportline’s Role in Global OEM & ODM Projects

As one of Asia’s leading carbon fiber hydrofoil board manufacturers, JCSportline provides full-spectrum OEM/ODM solutions—from CAD modeling and mold machining to hot-press production and QC validation. The company’s 66,000㎡ composite facility integrates autoclave systems, CNC tooling centers, and vacuum-curing lines. Boards undergo ISO and ASTM-compliant testing, including salt-spray, torsion, and pressure endurance before delivery. This ensures that every unit meets both mechanical and visual standards required by top-tier global clients.

Case Studies: Collaboration with International Brands

Several high-end water-sports brands now rely on JCSportline for their flagship hydrofoil series. These projects often include private-label manufacturing, customized weave patterns, and logo embossing during curing. By shifting production to one-piece carbon shells, brands report up to 30% fewer warranty claims and improved resale value due to consistent surface finish and structural reliability. Each collaboration reinforces the growing trust in Asian composite craftsmanship.

Global Logistics and Quality Assurance

Each batch of boards passes through a multi-stage QC inspection—visual surface check, weight verification, and tolerance measurement. Finished boards are sealed in anti-humidity packaging, cushioned by custom foam inserts, and labeled for export. JCSportline’s logistics team coordinates door-to-port shipping for global customers, ensuring safe arrival and traceability. From tooling design to final delivery, the process embodies the reliability that premium brands expect from an OEM composite supplier.

Electric Surfboard

Jcsportline Electric Surfboards feature one-piece carbon fiber construction, lightweight PU foam cores with local carbon reinforcements, full-board custom graphics, and marine-grade waterproof components for durable, high-performance water sports.

FAQ: Common Questions & Misconceptions

Why Does My Board Surface Show a Seam?

A visible seam across your hydrofoil board usually indicates split-mold construction — where two halves are bonded together after curing. This join line forms because the carbon layers stop and restart at the edges of each mold half. In contrast, one-piece molded boards use continuous carbon fibers within a single cavity, so there is no joint or resin overlap. Seamless boards maintain cleaner aesthetics and higher structural integrity under torsion and flex.

What’s the Real Difference Between One-Piece and Molded Boards?

The main difference lies in fiber continuity and bonding method. Traditional molded boards are glued together after curing, which interrupts load transfer and increases the chance of delamination. One-piece boards cure as a single integrated shell — the carbon, core, and inserts all fuse simultaneously. The result is stronger, lighter, and more durable construction, with no weak points where cracks or water ingress can develop.

How Can I Test if My Carbon Fiber Board Is Waterproof?

A simple immersion test can reveal water leakage. Place your board in a tank or bathtub filled with freshwater and observe for air bubbles along seams or inserts. If bubbles appear, it indicates trapped air or cracks in the bonding area. One-piece vacuum-cured boards should show zero bubbles, as the laminate and core are sealed under uniform pressure. After testing, dry the board thoroughly to prevent corrosion around metal hardware.

Is One-Piece Manufacturing More Expensive?

Yes — but the cost difference mainly comes from the CNC-machined aluminum molds and precision fixtures required for one-piece compression. These molds ensure ±0.3 mm tolerance and can be reused for thousands of production cycles. Although the initial investment is higher, the total cost of ownership (TCO) is lower due to reduced rework, lower defect rates, and longer product lifespan.

What’s the Typical Lead Time for OEM Projects?

Lead time varies depending on mold complexity and surface finishing requirements. Generally, new OEM/ODM projects take 45–60 days from CAD confirmation to first batch completion. Repeat orders are faster since molds, fixtures, and digital parameters are already established. JCSportline’s integrated workflow allows simultaneous mold production and prepreg layup scheduling to accelerate delivery.**